If stereo systems are one of the greatest devices to enjoy music. They aid us in listening to our favorite songs by converting electrical signals into sound waves that we are able to hear. The what is cca speaker wire is an important part of a speaker system. The voice coil is a length of wire that wraps around a cylinder that you embed into the speaker. This special wire is very important because it helps to convert electrical signals to motion that creates sounds as you listen to music.

The voice coil operates similar to a principle called electromagnetism. That is a fancy term for the fact that electricity can create magnetism. An electrical signal passing through the wire of voice coil creates a magnetic field around the coil. This magnetic field then interacts with an existing magnet embedded inside the speaker. This causes the voice coil to move back and forth. Its movement is what gives rise to various sounds, whether they be gentle songs or earth-shattering sounds. The voice coil moving back and forth is crucial for our enjoyment of the music.

Few components in a speaker system rank as highly as voice coils when it comes to how quality sound gets produced. The voice coil make-up and design can greatly affect the function of the speaker as the quality of the wire used and the number of times the wire is wrapped around the cylinder can have drastic results. IMPORTANT: Using better quality wire in a voice coil has the effect of creating a STRONGER magnetic field. This more powerful magnetic field is more effective at this, resulting in a clearer, louder sound, which allows for more complete enjoyment of the music.

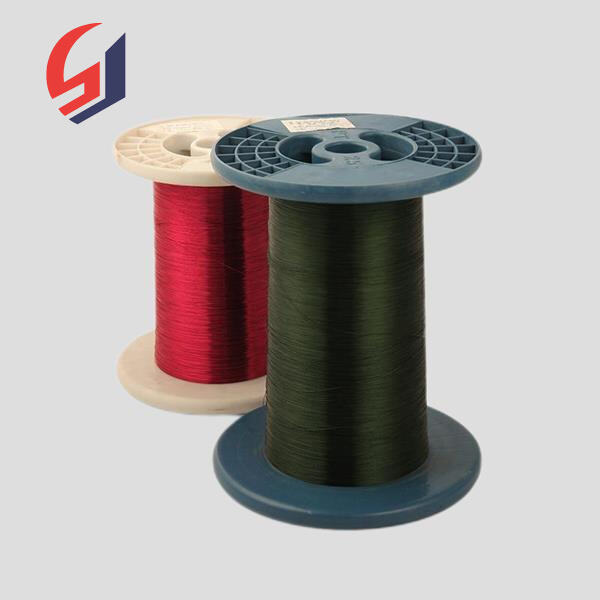

The fewer the amount of wraps of wire on the voice coil, the easier it is for the electrical signal to pass through. This helps the system work better without sacrificing any of the audio quality. The purpose of a good aluminum enameled wire is to drive more power to the speaker while preventing distortion in audio output. Which is indispensable for all music lovers who want to listen to their favorite music at its best.

One of the key components of the speaker system is the voice coil. For instance, a broken voice coil or malfunctioning will greatly affect the sound of the speaker. For example, a broken voice coil can cause the speaker to sound distorted, or even stop working altogether. Each time, the music lacks detail because of a broken voice coil, which is why swapping it after breaking it is crucial. Maintenance of voice coil is an important factor to keep speaker system in good working condition and we can enjoy good sound.

With speaker voice coils, there are essentially two types: Single Voice Coils (SVC) and Dual Voice Coils (DVC). A single voice coil means that there is only one wire wrapped around the cylinder, while a dual voice coil means that there are two wires wrapped around it. Their names give us a lot of information about how they work.

DVC systems are nice because there are more ways to configure them. This also means they’re suitable in more complex systems, such as those with multiple microphones or amplifiers. SVC system tends to be simpler and faster to install. They suit those who prefer a straightforward setup without complex wiring.

The modern production methods and strict quality control procedures in our enameled-wire manufacturing facilities allow us to efficiently deliver our products throughout the world. By working closely with our international logistics partners we can offer customized logistics solutions that meet the specific needs of our customers. Our delivery network in the world covers important ports, ensuring that goods reach their destinations promptly and safely. Sales staff at our company also offer online tracking solutions that keep our customers updated on the status of their shipment and improves transparency in the supply chain.

The quality is the main aspect of enameled copper wire. The factory undergoes many quality checks to make sure the quality of the products is in line with international standards and meet customer expectations. (1) Raw materials control from high-purity copper to top quality insulation lacquer, all raw materials undergo strict screening to ensure their performance is stable. 2.) Monitoring of the entire process. From wire drawing through to the process of enameling, each stage of production is subjected strict tests, including electrical performance as well as insulation voltage withstand and tensile tests to guarantee the reliability. (3) Complete certification Quality factories generally have the ability to pass ISO 9001 quality management system certification, as well as UL safety certification. SGS certification to increase the confidence of customers.

Our factory can design products to satisfy the specific requirements of our customers. We can also provide full service after the sale. Diversified specifications: Our factory produces enameled cables in different specifications like wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.

Enamel copper wire factories can create high-quality products at cheaper prices due to their production capacity on a large scale. (1) Production in mass: The manufacturing facility can react quickly to the demands of large orders and at the same time ensure the timeliness of delivery. (2) Cost reduction. By optimizing the production process and equipment factories are able to reduce consumption, increase output and lower unit costs and allow customers to be more competitive in their prices.