Hello, young reader! In this article, we will talk and learn about CCA speaker wire. This might sound a little tricky or confusing at first, but do not fret! In this article, you will learn everything you need to know about CCA speaker wire and what it is at the same time.

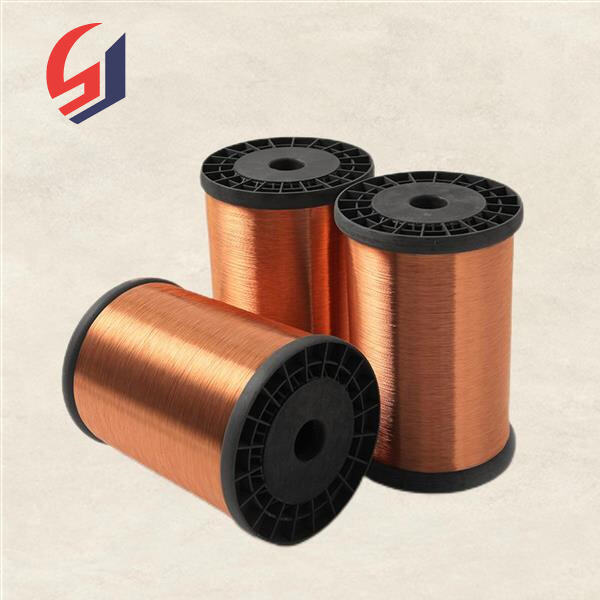

CCA is short for "copper clad aluminum. Which indicates that the wire is aluminum content, which is the core component of the wire is aluminum content, with a copper sheath wrapped around it. Copper is one of the best materials to transfer electricity. That allows for regularity of sound to travel proper through the wire. Aluminum, it turns out, doesn't carry electricity as well, but it comes with its own benefits. CCA wire is also cheaper and lighter than copper, which makes it a favorite for many people. This is cheap but decent quality sound wire and most popular.

The primary reason why CCA speaker wire is a popular choice is simply that it is cheaper than other forms of speaker wire. The quality will suffice without having to get a mortgage. This is why its another reason people like it because light weight. Light wires are very useful when using a large amount of speaker wire in your home or car. Heavier wires can be a challenge to install, as they can add a significant weight burden to the walls or the vehicle. In addition, some people believe that the gap of audio quality between CCA wire and other types of wire is not so large, one other reason that makes them choose CCA wire.

Pros and Cons of CCA Speaker Wire The positives are that it is less expensive and lighter than most other types of wire. This certainly facilitates the installation of the wires, be it for a home audio system or speakers in the car. But CCA wire does have some drawbacks. [Some believe CCA wire doesn't do as good a job transferring the sound as other types of wire, which means the sound could lack clarity (or punch). Also, the core itself is aluminum and the wire can then be broken more easily when bent or twisted too much. Copper wire is stronger and can flex more without breaking, making it more durable in some cases.

Here are tips on how to select the right CCA speaker wire, if you decide to use it for your sound system. But first, you have to choose an appropriate gauge wire for your needs. The thicker wire will use a wire capable of transporting the electrical signal better and thus increase sound quality. Secondly, take notice of the gauge of the wire. The lower the gauge number, the thicker the wire. 16 or 18-gauge wire works great and should be adequate for most average use. If you are wiring things over longer runs or have high-power speakers, you should think about using a more heavy wire for better performance. Third, choose a wire that is designed to be "oxygen-free. This means that the wire is designed to resist rusting, over time, which can be very critical, as the sound can change, and get worse, when the wire rusts.

CCA wire is not the only type of speaker wire available on the market. A wire such as copper is a suitable material if you need something that is durable and malleable. It also can better handle bending and twisting, making it easier to install in tight places. Another is solid-core wire, though that stuff is extremely rigid. That can make it difficult to work with, especially if you have to fit it into snug spots. If sound quality is your supreme concern, consider using silver wire. Silver is a very good electrical conductor, meaning it transmits sound very well. At the same time, silver wire is very pricey and not necessarily for everyone.

Copper wire factories that are enamel can produce high-quality products at cheaper prices due to their scale production capability. (1) Mass production: The factory is able to react quickly to the demands of large orders and at the same time ensure that the delivery time is on time. (2) Cost reduction through a more efficient production and optimizing equipment factories can cut down on consumption and increase the rate of output, thus reducing unit cost and giving customers more competitive cost.

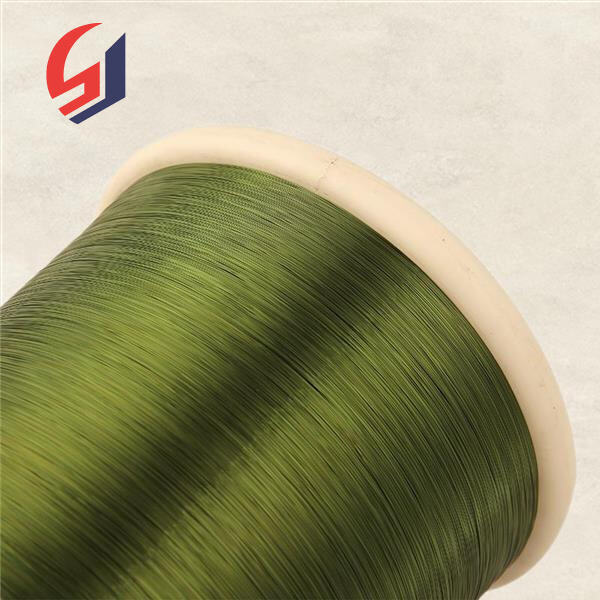

Our enameled wire factory can customize the products according to customer's special requirements and also provide full after-sales support. Diversified specifications: The factory can produce enameled wires in a wide selection of specifications. This includes different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of application scenarios.

Quality is the primary element of enameled copper wire. The factory undergoes many quality control stages to make sure that the product meets international standards and meet customer needs. (1) Raw materials control: From high purity copper, to the highest quality insulating lacquer, raw materials are subjected to rigorous screening in order to ensure stability. 2) Monitoring of the entire process. From wire drawing to the final stage of enameling, every step of production is subjected to rigorous tests like electrical performance and insulation voltage withstand and tensile tests to guarantee high-quality and reliability. (3) Full certification The majority of quality factories get ISO 9001 quality management system certification and UL safety certification. SGS certification that increases the trust of the customer.

Our wire factories that are enameled ensure efficient delivery of products worldwide thanks to the latest manufacturing technology and rigorous quality control. In collaboration with our logistics partners in the world we can create customized logistics solutions to meet the specific needs of different customers. Our global network of delivery partners includes key ports to ensure the goods arrive at their destination quickly and safely. Sales staff at our company also offer online tracking services that keep our customers up-to-date on the progress of their shipments, improving supply chain transparency.