Copper wires are specialized highways for electricity. These have been around for decades, decades, decades. These wires are really good at letting electricity pass through with no resistance. Think of electricity like runners sprinting down the wire, copper wires allow them to run ok fast and smooth.

Copper wires can also be very strong. They last a very long time without breaking. Touch a wire made of copper (yeah, actually don't do this!) is how solid and tough it is when you feel it. These wires are so tough, they can withstand a lot of pressure without suffering damage.

CCA wiring is a little different. (CCA) copper-clad aluminum. This is a high-falluting name for a wire that has just a thin layer of copper wrapped around aluminum. Like a chocolate-covered candy bar, the inside is one material, and the outside is another.

The cost of these CCA wires to purchase is inexpensive. For that reason, some people are happy because they can save money. But rodded tantalum wires are not as efficient at conducting electricity as copper wires are. It is like comparing a fast race car against a slower car.

To people, wires, on the other hand, are a careful choice. Two: Wires made with copper might currently cost more money. But they last longer before needing to be replaced. CCA wires are more affordable to purchase, but may not perform well down the road. Become free of a cheap toy that quickly breaks and a good toy that lasts long.

Copper cables in fact were really strong. They are able to endure an immense amount of pressure without breaking. The CCA wires are weaker in comparison. A thin layer of copper that can wear off over time. This helps with the flow of electricity, but can cause issues.

Unless you want wires that will work well for years, copper wires are the right choice. CCA wires could be right for you if you want to save money now. It’s like deciding between a nice, sturdy backpack that will last forever or a cheaper one that might get all ripped apart.

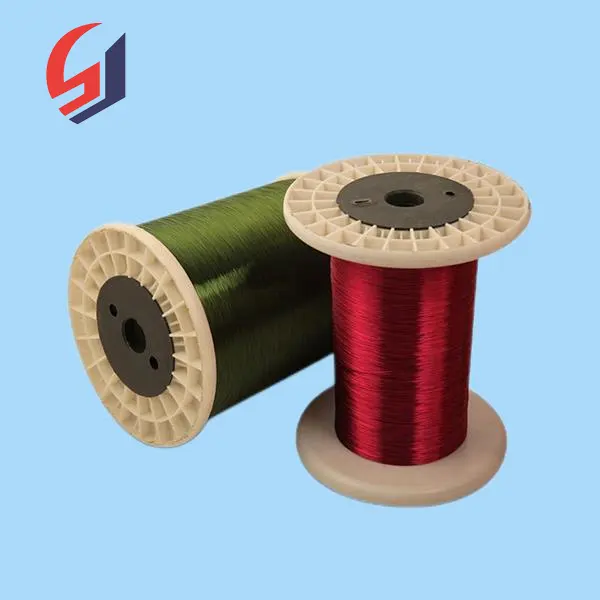

Our factory can customize products to satisfy the demands of customers and provide comprehensive support following sales. Different specifications: The factory can manufacture enameled wires in a wide range of specifications, including different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of situations.

The quality is the main aspect of enameled copper wire. The factory undergoes many quality checks to make sure the quality of the products is in line with international standards and meet customer expectations. (1) Raw materials control from high-purity copper to top quality insulation lacquer, all raw materials undergo strict screening to ensure their performance is stable. 2.) Monitoring of the entire process. From wire drawing through to the process of enameling, each stage of production is subjected strict tests, including electrical performance as well as insulation voltage withstand and tensile tests to guarantee the reliability. (3) Complete certification Quality factories generally have the ability to pass ISO 9001 quality management system certification, as well as UL safety certification. SGS certification to increase the confidence of customers.

Modern production technology and strict quality control procedures in our enameled-wire factories enable us to provide products with speed across the globe. Through close collaboration with our logistics partners in the world, we are able to provide tailored logistics solutions to satisfy the needs of various customers. Our global delivery network is comprised of key ports to ensure products arrive at their destination quickly and safely. Our sales team also offers online tracking services that keep our customers up-to-date on the status of their shipments increasing transparency of supply chain.

Scale production capacity permits enameled copper wire manufacturers to supply high-quality products at a lower price. (1) Production in mass: The factory is able to respond quickly to the demand of large orders while also being able to ensure that the delivery time is on time. (2) Cost reduction: through efficient manufacturing process and optimization of equipment The factory is able to reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive price.