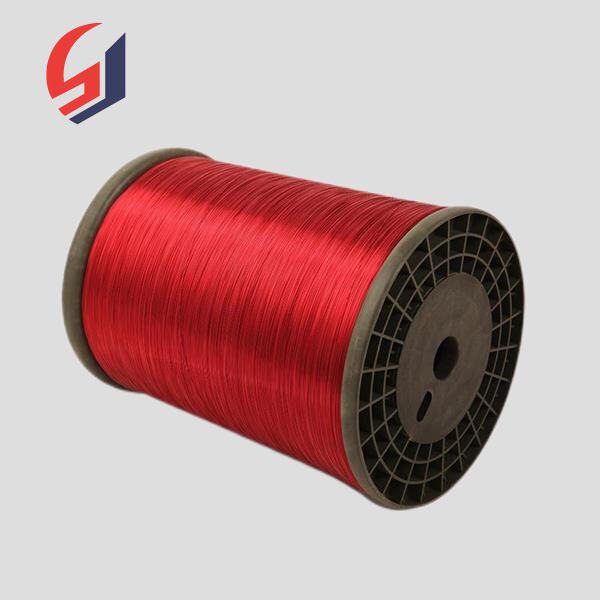

It brings us lots of joy to share our Super Enamelled Aluminium Wire with everyone, here in Shenzhou Cable. Why this type of wire is special because it used to carries the electricity from one place to another. Super is known as super because it is done in a new manner with quality raw materials which help it work great and effectively.

Super Enamelled Aluminium Wire Circumference is perfect for projects that require high-level accuracy so it can be employed in devices where it is very important to get things exactly right. One reason for this is one of its applications, e.g. in the context of refrigerators or air conditioners. These appliances must perform in order to help keep food cold, or cool down a room. "Sending these signals using our special wire helps them work great and minimize energy, so they can do their job without wasting energy.

Super Enamelled Aluminium Wire is strong and enables handling of hot and cold temperatures, which is why it is one of the best metals used. That is because this wire is resistant to rust and damage, which makes it ideal for all sorts of electrical jobs. It can also be long-lasting, which is why you often see it in machines with moving components, such as motors. These machines require serious durable wire to maintain without breaking.

Energy conservation is great for the planet, and for people’s pocketbooks. We have a better option, Super Enamelled Aluminium Wire, if you still have the usage of all your appliances but want to save some money.

SEAW (super enamelled aluminium wire) Rebooting Electric Motor design and assembly. Machine Learning and AI It is one of the game-changer because it assists engineers to create machines that are better and more efficient than never before. This special wire also allows engineers to install machines that are smaller and lighter in size while still being fully efficient and powerful. This matters because smaller machines are often easier to use and fit in different spaces.

We are Shenzhou Cable, specializing in Super Enamelled Aluminium Wire that can be customized for your needs. So we can also make wire that is custom designed for your application. When you need wire for a big project or a small one, we have you covered. Now your electrical appliances will perform excellent when you work with us and high-quality wire.

An extensive use of Super Enamelled Aluminium Wire is in high end job and industrial applications. TERMINAL_VOCABULARIES_BIT You will see this in key sectors such as aerospace, automotive, and electronics. These industries need wire that is very efficient, incredibly strong and utterly reliable. It satisfies all the requirements and beyond; hence, our Super Enamelled Aluminium Wire comes in very handy for these needs.

Copper wire manufacturers in enamel are able to produce top-quality products for a lower price due to their capacity to produce large quantities. 1.) Mass production: The manufacturing facility can quickly respond to large orders and ensure prompt delivery. (2) Cost reduction. By optimizing the production process as well as equipment it is in a position to cut down on production, reduce waste, and reduce unit costs and allow customers to be more competitive in their prices.

The latest production techniques and stringent quality control in our enameled-wire manufacturing facilities allow us to deliver products efficiently across the globe. We cooperate with our international logistics partners to create customized logistics solutions that satisfy the needs of our customers. Our global delivery network is able to cover important ports, ensuring that your products get to their destination promptly and safely. Furthermore our sales team provides online tracking services to keep customers updated on the progress of their shipment in real-time, increasing the transparency of supply chains and customer satisfaction.

Quality is the key component of enameled copper wire. The factory undergoes many quality control procedures to ensure the products are up to standards of international quality and meet the customer's expectations. (1) Control of raw material: from high purity copper to the highest quality of insulation varnish, the raw materials are rigorously screened to ensure stable performance. 2.) Monitoring throughout the process. From wire drawing to enameling, each step of production goes through rigorous testing such as electrical performance, insulation voltage withstand, and tensile tests, to ensure quality and safety. (3) Complete certification Quality factories generally are able to obtain ISO 9001 quality management system certification, as well as UL safety certification. SGS certification, to boost customer confidence.

Our factory can tailor products to satisfy the specific requirements of customers and provide comprehensive service after the sale. Multiple specifications: Our factory can make enameled wires with a wide spectrum of specifications, including different wire diameters, enamel thicknesses, temperature ratings and insulation ratings to fit a variety applications.