Ever thought about how machines and appliances work? To work effectively, they require something known as electrical systems. These systems move electricity from place to place using wires. But not all wires are created equal — some wires can withstand higher temperatures than others. Hence, the magic of !

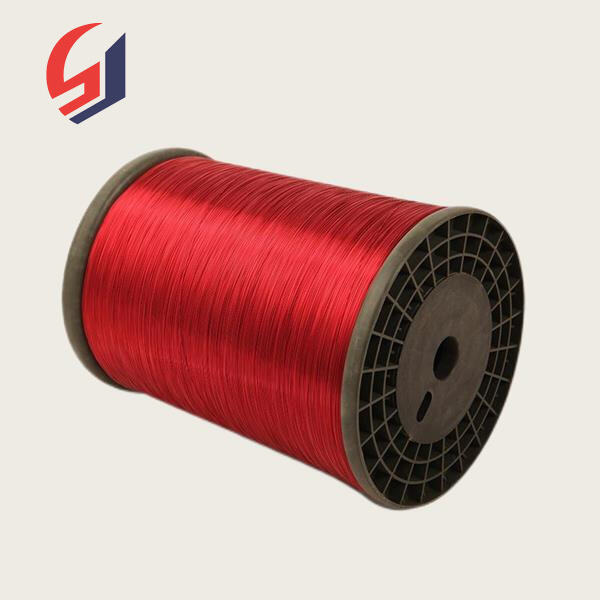

Super enamelled aluminium winding wires are special wires which are capable to endure hot temperature without breaking or getting damaged. That makes them ideal for critical machineries such as electric motors, transformers and generators that need to perform in hot and harsh conditions. Shenzhou Cable is one of several manufacturers of such high-grade cable. They make sure your machines and appliances can keep performing properly, even when its forces outside or inside the equipment are boiling.

Electrical systems exist all around us! They help illuminate the lights in our homes, power the TVs we watch and the cars we drive. These systems use wires to transport electricity, an errant zap makes insulation a must. It's like a protective cover on the wires, insulation. It protects them from being damaged. Where insulation is bad, wires may short-circuit — potentially causing fires or other hazardous problems.

Electric motors are found in a wide variety of machines and appliances around you such as vacuum cleaners, washing machines and factory machinery. Winding wires are required to run these motors. You can be assured of the efficient functioning of your electric motors, saving time and money, when you select super enamelled aluminium winding wires from Shenzhou Cable.

Super enamelled aluminium winding wires are good because they transmit electricity better than other kinds of wires. That means your motors will consume less power to perform the same task. And by consuming less electricity, you'll in turn save money on your electric bill over time. Not only that, but these wires are designed to live longer, so you won’t have to replace them as frequently. This is relatively easy to do and economical.”

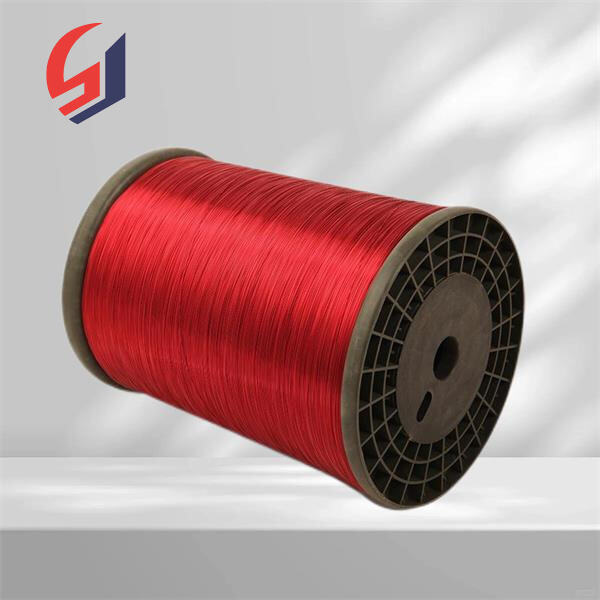

Last but not least, Shenzhou Cable enamelled aluminium winding wires will save energy for your machines and appliances as well. These wires are more efficient at transferring electricity than other wires. Because they carry electricity more efficiently, your machines and devices will use less electricity to operate, very potentially saving you money on your power bill.

Even so, enamelled aluminium wires are reduced waste energy. Lower electricity usage means lower overall energy waste. It really is good for the environment! It also means less power plants generate power which is fatal to our planet. With these special wires, you are making not only a sensible selection for your machines, yet also saving the Planet.

Our wire factories that are enameled ensure efficient delivery of products globally thanks to advanced production technology and strict quality control. Working closely with our logistics partners in the world We are able create customized logistics solutions to meet the specific needs of our customers. Our global delivery network covers major ports, ensuring that products reach their destinations efficiently and securely. Sales staff at our company also offer online tracking solutions that inform our customers of the status of their shipment, improving supply chain transparency.

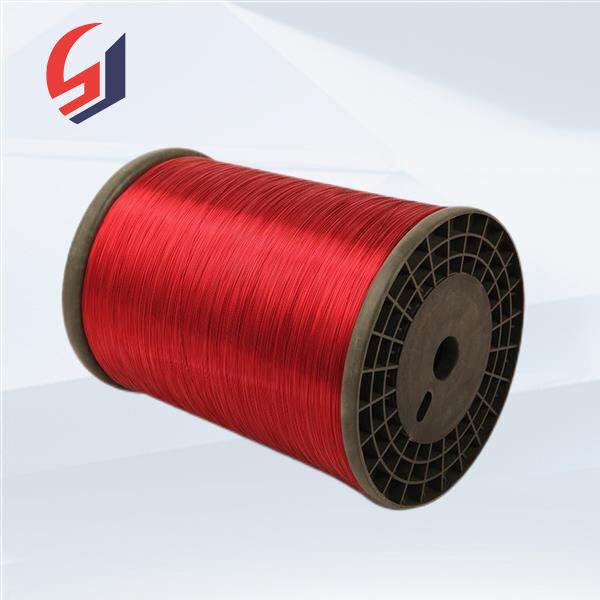

Copper wire manufacturers in enamel are able to produce top-quality products for a lower price due to their capacity to produce large quantities. 1.) Mass production: The manufacturing facility can quickly respond to large orders and ensure prompt delivery. (2) Cost reduction. By optimizing the production process as well as equipment it is in a position to cut down on production, reduce waste, and reduce unit costs and allow customers to be more competitive in their prices.

Our factory is able to customize products to meet the requirements of the customers. We also provide complete support after sales. Multiple specifications: Our factory is able to produce enameled wires that meet a broad variety of specifications, which include different diameters of wire, enamel thicknesses, temperatures, and insulation ratings to suit various situations.

The high-quality of enameled wire copper is of paramount importance. The factory goes through numerous stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Control of raw materials From pure copper to high quality insulation varnish, the raw materials are rigorously screened to ensure their stability. (2) Whole-process monitoring: From drawing wires to enameling each stage of production goes through rigorous testing, such as tensile strength as well as electrical performance and voltage withstand tests, to guarantee the product's reliability. (3) Complete certification: Quality factories usually have the ability to pass ISO 9001 quality management system certification as well as UL safety certification. SGS certification to increase the trust of the customer.