Wire is a type of thin, flexible material that carries electrical impulses from one location to another. It works like a road for electricity, connecting things that use power, such as lights, computers and televisions. Any time you hear CCA wire, that is a common type of wire a lot of people use.

CCA means Copper Clad Aluminum. Thus, CCA wire is actually two kinds of metals: copper and aluminum. Within the wire is aluminum, a lightweight metal. There is also thin layer of copper, a very conductive metal, on the outside of the wire. Due to this unique combination, this Copper-clad aluminum wire is cheaper than pure copper wire, but it retains some of the beneficial characteristics of copper that are useful.

CCA wire is light and easy to handle, which is why it is often used in cars and boats. It is lightweight, which can matter a lot for performance, as it does not add too much weight to cars. But there are key considerations you must account for when handling CCA wire. For instance, CCA wire isn't quite as conductive as pure copper wire. That means it may not be ideal for devices that require a significant amount of power to function as intended. Also, CCA wire may not be as durable as pure copper wire, particularly under harsh conditions.

When you're trying to decide if you should go with CCA wire or pure copper wire, consider what your project really needs. For a light and cheaper wire, you can go with CCA wire. It often does a pretty good job on many everyday tasks. However, if you require a wire with exceptional conductivity that will see a lot of use for long periods of time, then you'd want pure copper wire. They are excellent for flexibility, but you need to match the wire to the job so it flows and doesn't go bad.

There are multiple advantages to using CCA wire in cars and boats. The first reason CCA wire does not rust or corrode is that its CCA makes it more long-lasting especially in harsh or wet environments. This is particularly necessary in areas where water is likely to be present, such as inside of boats. It’s also light, which is critical when the weight impacts speed and efficiency. So handling CCA wire is pretty easy. This implies it is much faster and easier to install saving you realmoney and time while installing the configuration.

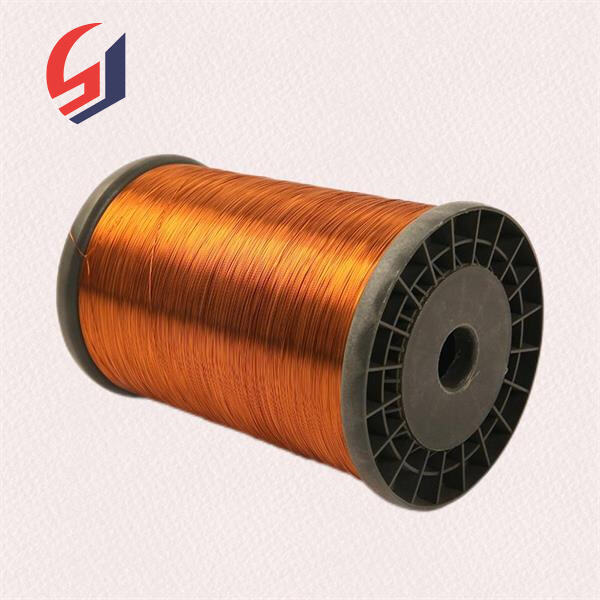

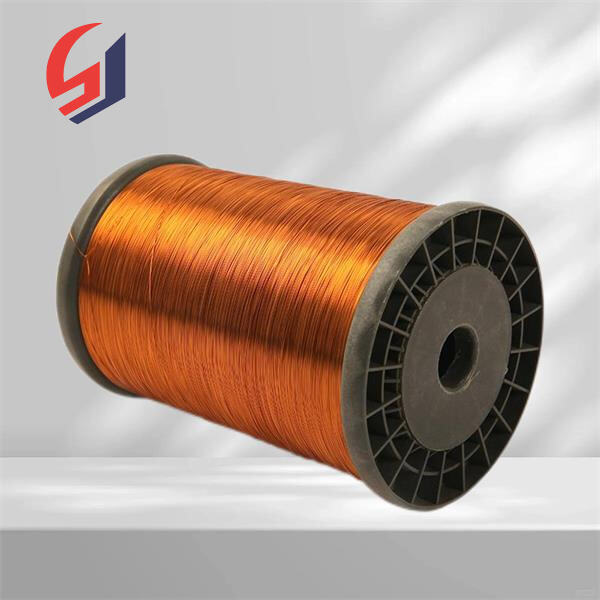

Copper wire factories that are enamel can produce high-quality products at cheaper prices due to their scale production capability. (1) Mass production: The factory is able to react quickly to the demands of large orders and at the same time ensure that the delivery time is on time. (2) Cost reduction through a more efficient production and optimizing equipment factories can cut down on consumption and increase the rate of output, thus reducing unit cost and giving customers more competitive cost.

Our enameled wire factory is able of customizing products to meet customers' particular requirements. They also provide complete after-sales service. Diversified specifications: The factory is able to produce enameled wires that meet a broad variety of specifications, which include various wire diameters, enamel thicknesses, temperature ratings, and insulation ratings to fit a variety different applications.

Our wire factories that are enameled ensure efficient delivery of products worldwide thanks to the latest manufacturing technology and rigorous quality control. In collaboration with our logistics partners in the world we can create customized logistics solutions to meet the specific needs of different customers. Our global network of delivery partners includes key ports to ensure the goods arrive at their destination quickly and safely. Sales staff at our company also offer online tracking services that keep our customers up-to-date on the progress of their shipments, improving supply chain transparency.

The high-quality of enameled wire copper is of paramount importance. The manufacturing facility goes through a variety of quality checks to make sure the quality of the products is in line with standards set by international standards and satisfy customer needs. (1) Control of raw materials From pure copper, to high quality insulation lacquer, all raw materials undergo strict screening to ensure stable performance. (2) Continuous monitoring of the process: From wire drawing to enameling, each stage of production goes through rigorous testing including tensile strength along with electrical and insulation voltage withstand tests, to ensure the quality of the product. In order to increase customer confidence Quality factories are typically certified with ISO 9001 for their quality management system, as well as UL Safety certification.