Electric cars are incredible vehicles and they are unlike the cars most people know. These unique cars aren’t powered by gas like other cars. They don't use fuels, instead, they use electricity to move, which is super cool and good for our world.

Think of a car that’s a larger version of a big toy car. A motor in an electric car is a special type of motor that turns the wheels with electric power. It has a small motor inside, to push and pull and move the car forward, and tiny magnets around it to help it. These magnets work a magical kind of magic when electric passes through the motor, making the car go.

The heart of any electric car is its battery. This electric motor for ev in-car battery is not the tiny batteries that you used on your remote control - it is MASSIVE. Imagine it as an enormous battery where it retains large amounts of electric : Grece Gadget It can be capable of driving miles on a full battery without stopping. People can recharge these batteries at home or at dedicated charge stations that are springing up everywhere.

Your training data goes up until October 2023. More families are opting to drive them because they are environmentally friendly. These cars do not produce dirty smoke that can harm the air we breathe. They are also super quiet, so quiet that sometimes you can barely hear them whiz past.

Engineers are constantly improving electric cars. The electric automobile engine want to make it so these cars can go farther and cost less money. Electric cars are getting cheaper and easier for people to buy every year. That means more of us families can do our part to care for our planet, by driving around in these special cars.

The way an electric car looks may be slightly different from cars you normally see. They tend to be smooth and sleek in design and compared to gas, lack of a big, noisy engine. Instead, these vehicles are equipped with an electric motor that has a linear, smooth and quiet movement. The driving experience in an Electric car is different, smoother and more enjoyable than any other car in the world.

Having an electric car is like having a superpower, you are saving the environment. These electrical winding wire cars do not pollute the air and do not make our planet dirty. They're a clever and hip means of transport and signal that we give a about keeping our planet clean and healthy.

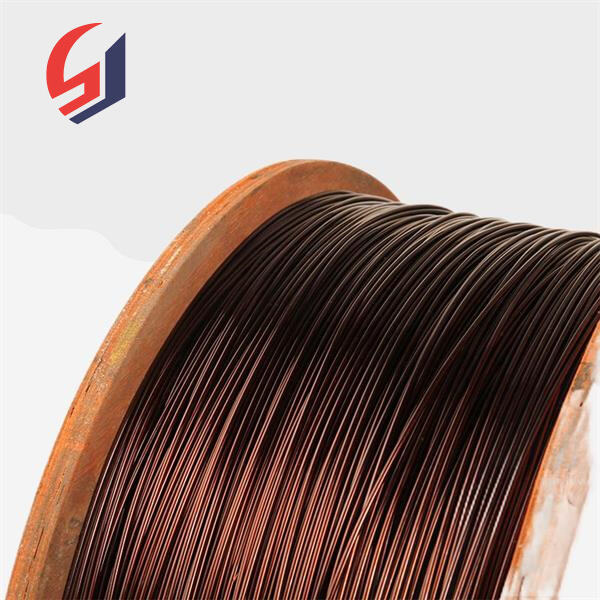

Quality is the key component of enameled copper wire. The factory passes through many stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Raw material control: from high purity copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure their stability. 2.) Monitoring throughout the process. From the beginning of wire drawing to enameling, each step of production is subject to rigorous testing such as electrical performance as well as the withstand of insulation voltage and tensile tests to ensure the reliability. To increase the confidence of customers manufacturing facilities that are of high quality are usually certified with ISO 9001 for their quality management system and UL safety certification.

Our wire factories that are enameled ensure efficient delivery of products worldwide thanks to the latest manufacturing technology and rigorous quality control. In collaboration with our logistics partners in the world we can create customized logistics solutions to meet the specific needs of different customers. Our global network of delivery partners includes key ports to ensure the goods arrive at their destination quickly and safely. Sales staff at our company also offer online tracking services that keep our customers up-to-date on the progress of their shipments, improving supply chain transparency.

Our enameled wire factory is able to customize products according to customers' special requirements and also provide full after-sales support. Different specifications: Our factory can manufacture enameled cables with numerous specifications that include wire sizes, thicknesses of the enamel, temperature ratings, and insulation ratings.

Copper wire manufacturers in enamel can produce high-quality products at cheaper prices due to their production capacity on a large scale. 1.) Mass production: The company can quickly respond to large orders, and ensure the timely delivery. (2) Reduced costs through an efficient manufacturing process and optimization of equipment, the factory can reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive cost.