An electric car has the appearance of any ordinary car, but it is different. It uses electricity stored in a large battery, rather than gas from a pump. Imagine this battery as an enormous phone charger that powers the car’s movement. These cars drive quietly, smoothly, and very differently than the cars our moms and dads and grandparents drove.

It’s like you are playing with a remote-control car. You press the button, and the car starts moving, right? An electric car works in the same way almost! When a driver presses the gas pedal, electricity runs from the battery to the motor. Then the motor turns the wheels. The higher the current inputted into the motor, the faster the car travels.

When the driver presses the brakes to slow down or stop, the motor helps slow the car down. It’s as if the car is catching its breath. This is unlike gas cars which stops using brake. Electric cars can slow down by using their motor, and they can even generate some extra electricity while they’re at it!

Contrary to popular belief, electric cars are fantastic assistants for the planet! Gas cars spew dirty smoke; they do not. As a gas car drives, it emits harmful gases that can damage the air we breathe. But electric cars? They ensure that the air remains clean and fresh.

Electric Cars: The Future More and more people are using electric cars to show that they care about the environment, our world and the future of the next generations. Each electric car is an independent force fighting against pollution and climate change.

Some are half thought-out anyway; others are bad science, outright lies or at least simplistic; in both cases, scientists and car makers are busy improving the electric car. They’re building batteries that can hold more energy and charge faster. Some electric vehicles are now capable of traveling hundreds of miles on a single charge!

One day, an electric car may be what most cars on the road can be. Children today are being raised in a world where cars that aren’t loud and filthy are becoming the norm. And by going electric, we are making the world a cleaner, healthier place for all.

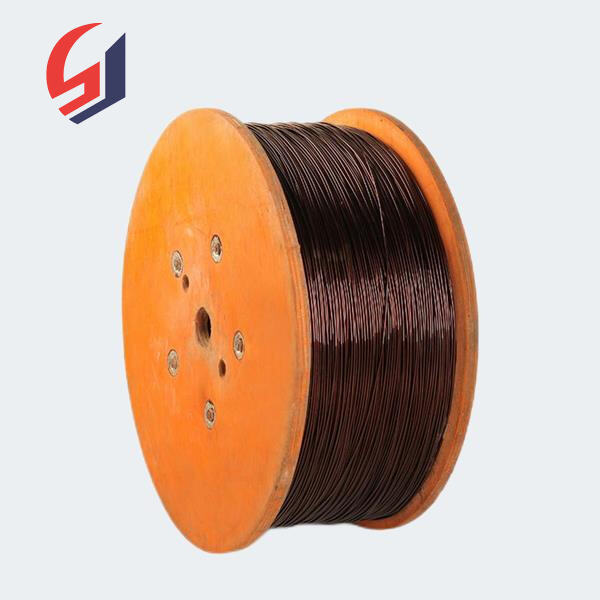

The high-quality of enameled copper is of paramount importance. The manufacturing facility goes through a variety of quality control procedures to ensure that the product meets standards of international quality and meet the customer's requirements. (1) Control of raw materials from pure copper to premium insulating lacquer, the raw products undergo rigorous screening to ensure their performance is stable. 2.) Whole-process monitoring. From wire drawing to enameling, every stage of production is subjected strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure quality and safety. In order to increase customer confidence, quality factories are usually certified by ISO 9001 for their quality management system and UL Safety certification.

Modern production technology and strict quality control procedures in our enameled-wire manufacturing facilities allow us to provide products with speed across the globe. In collaboration with our logistics partners in the world we are able to offer customized logistics solutions that meet the specific needs of our customers. Our global network of delivery partners includes important ports to ensure that the products reach their destinations quickly and safely. Our sales team also offers online tracking solutions that keep our customers up-to-date on the status of their shipment and improves transparency in the supply chain.

Our factory is able to customize products to meet the requirements of the customers. We also provide complete support after sales. Multiple specifications: Our factory is able to produce enameled wires that meet a broad variety of specifications, which include different diameters of wire, enamel thicknesses, temperatures, and insulation ratings to suit various situations.

Copper wire factories that are enamel are able to produce top-quality products for an affordable cost because of their scale production capability. 1) Mass production: The manufacturing facility can rapidly respond to orders of large size and guarantee timely delivery. (2) Reduced costs through an efficient production and optimizing equipment The factory is able to reduce waste and increase output rate so that the unit price is reduced and allowing customers to enjoy a better price.