Coils are special circular wires. They look like a close twist and assist many devices carry out their duties. Coils can be found in a lot of everyday items and systems, and are an important part of making our machines function.

You can image taking a wire and wrapping it around and around a center point: This is what makes up a aluminum enameled wire. Picture stretching out a piece of wire and carefully twisting it in a circle, as you might coil a rubber band about your finger. This forms a configuration that resembles a coil. Wrapping wire tightly in a coil. These coils assist machines operate, by freezing electricity and developing tiny magnetic fields which can do incredible ambitions.

Solenoids are a special type of super enamelled aluminium winding wires. These coils are tightly wound around a metal core. These are time-like friends inside a machine. These solenoids can cause motion or perform functions when electricity is fed into them. Solenoids are a component in doorbells — the ringing ones — or in car music players that allow you to hear your favorite songs.

Coils can perform unique functions with electricity. They are like invisible wires of magic that can transform electricity into other materials we utilize. In a speaker, a coil helps create sound by vibrating a piece really fast. This rapid movement generates the sound waves that allow you to hear the music, the voices or the sounds that come from a radio or a phone.

You can see coils in many things we use on a daily basis. They make radios make music, TVs show pictures and phones do what phones do. [Coils so small you can barely see them, but they are still doing important work. Without coils a lot of machines we love would either not work properly, or work at all.

Many years ago, a scientist named Michael Faraday discovered how coils can move electricity. He learned that moving a magnet near a wire can generate electricity! So this was a huge discovery that gave us insight into how machines, through this motion, could do work by using electricity.

Coils may seem basic, but they are little heroes in our devices. They can transform electricity to sound, assist machines in their motion, and do so much more. So next time you tune in to music or fire up a device, think of those little coils doing the hard work inside.

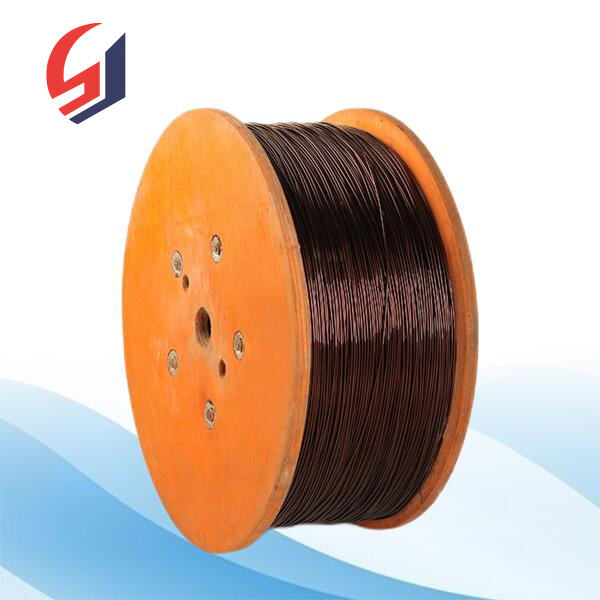

Copper wire manufacturers in enamel are able to produce top-quality products for a lower price due to their capacity to produce large quantities. 1.) Mass production: The manufacturing facility can quickly respond to large orders and ensure prompt delivery. (2) Cost reduction. By optimizing the production process as well as equipment it is in a position to cut down on production, reduce waste, and reduce unit costs and allow customers to be more competitive in their prices.

The quality is the main component of enameled wire. The factory goes through numerous levels of quality inspections to ensure that the products are in compliance with the requirements of international standards and customers. (1) Control of raw materials from pure copper, to high quality insulating lacquer, the raw materials are subjected to rigorous screening in order to ensure stable performance. 2.) Whole-process monitoring. From the beginning of wire drawing to the process of enameling, each stage of production is subject to strict tests, including electrical performance as well as the withstand of insulation voltage and tensile tests to ensure reliability. (3) Full certification: Quality factories usually have the ability to pass ISO 9001 quality management system certification as well as UL safety certification, SGS certification to enhance the confidence of customers.

The modern production methods and strict quality control procedures in our enameled-wire manufacturing facilities allow us to efficiently deliver our products throughout the world. By working closely with our international logistics partners we can offer customized logistics solutions that meet the specific needs of our customers. Our delivery network in the world covers important ports, ensuring that goods reach their destinations promptly and safely. Sales staff at our company also offer online tracking solutions that keep our customers updated on the status of their shipment and improves transparency in the supply chain.

Our factory is able to customize products to meet the requirements of the customers. We also provide complete support after sales. Multiple specifications: Our factory is able to produce enameled wires that meet a broad variety of specifications, which include different diameters of wire, enamel thicknesses, temperatures, and insulation ratings to suit various situations.