In the world of electrical, Copper Clad Aluminium Wire is a common choice. So, a lot of people ask, 'Is this type of wire a good choice for the homes? In order to help you make this decision, let us take a closer look at the pros and cons of copper clad aluminum wire.

The main reason people choose copper clad aluminum wire is that it costs less than pure copper wire. Because aluminum is cheaper than copper. It is created by wrapping thin layer of copper around an aluminum core. This design provides you some of the benefits of copper wire at a lower price. For those looking for a cost-effective yet a high quality wire for their electic needs, copper clad aluminum wire is a smart option.

Electrical wiring is full of concerns regarding safety. Many people ask whether copper clad aluminum wire is safe to use in the house. Some believed it was safe; others raised concerns, saying it could be risky. One possible issue: Copper rusts or corrodes when it comes in contact with aluminum. This can cause corrosion creating the potential for electrical fires, and none of us want that!

But new technology has incrementally made copper clad aluminum wire safer than it once was. Manufacturers have developed a unique protected copper coating on aluminum wire. This coating prevents the copper from rusting so it is less likely to catch fire. Thanks to these improvements, many feel this type of wire is safe for use in the home.

Copper clad aluminum wire2 however is another issue that you should consider. Copper wire is inherently better than aluminum wire at carrying electricity. This allows electricity to pass through copper more easily and efficiently than through aluminum. For this reason, copper wire is favored by most individuals for all types of electrical applications.

This problem is avoided by copper clad aluminum wire, which has a copper layer on the outside. If you find it difficult to believe, roll the copper copper for carrying electricity and aluminum core for supporting. Also, the thickness of the copper layer makes the wire to more or less perform. If the copper layer is too thick, it might dilute the power of the electricity, leading to performance issues.

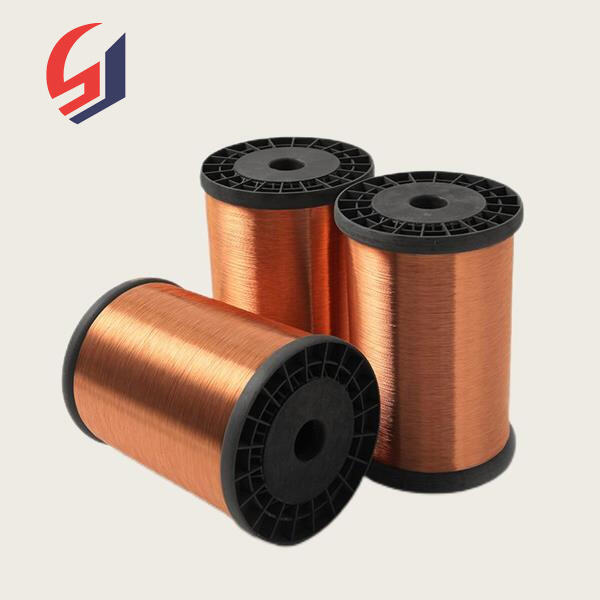

This is commonly done using copper clad aluminum wire, which is a more cost-efficient alternative to pure copper wire. It offers many of the same advantages as copper wire, but at lower cost. Copper wire is good in conductivity and durability, so it could last long. For a lot of people, the expensive price of copper can be a downside. This is where the copper clad aluminum wire comes into play. It is great for the people who want the benefits of copper wire, but do not want to pay a lot.

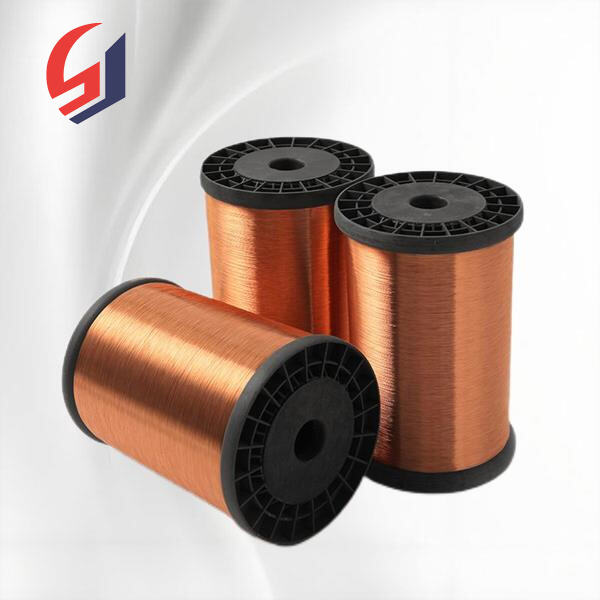

Our factory can customize products to satisfy the demands of customers and provide comprehensive support following sales. Different specifications: The factory can manufacture enameled wires in a wide range of specifications, including different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of situations.

The quality is the main aspect of enameled copper wire. The factory undergoes many quality checks to make sure the quality of the products is in line with international standards and meet customer expectations. (1) Raw materials control from high-purity copper to top quality insulation lacquer, all raw materials undergo strict screening to ensure their performance is stable. 2.) Monitoring of the entire process. From wire drawing through to the process of enameling, each stage of production is subjected strict tests, including electrical performance as well as insulation voltage withstand and tensile tests to guarantee the reliability. (3) Complete certification Quality factories generally have the ability to pass ISO 9001 quality management system certification, as well as UL safety certification. SGS certification to increase the confidence of customers.

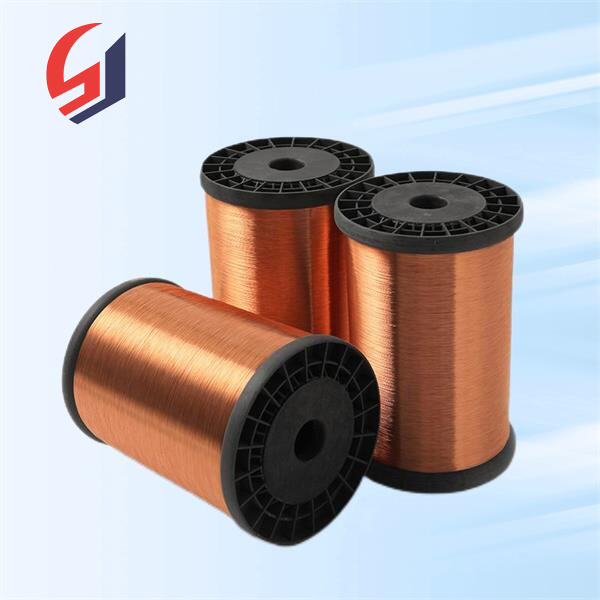

Our wire factories that are enameled ensure efficient delivery of products globally thanks to advanced production technology and strict quality control. Working closely with our logistics partners in the world We are able create customized logistics solutions to meet the specific needs of our customers. Our global delivery network covers major ports, ensuring that products reach their destinations efficiently and securely. Sales staff at our company also offer online tracking solutions that inform our customers of the status of their shipment, improving supply chain transparency.

Copper wire factories with enamel coating can create high-quality products at an affordable cost because of their scale production capability. (1) Mass production: The factory is able to respond quickly to the needs of large orders, while at the same time guaranteeing the speed of delivery. (2) Reduced costs through an efficient production process and equipment optimization manufacturing, factories can decrease production waste and improve output and reduce unit cost and giving customers more competitive price.