They hand off a baton, a small stick, to one another as they run toward the finish line. Relay races are common in highly competitive environments such as schools, colleges, and even major professional sports events. Let’s explore the electric world of relay racing, why it matters, and some practical tips to help you win.

Relay rasis are all about speed, teamwork, and precision. The aluminum enameled wire Runners need to be quick and to work together to succeed. For most relay races, a team consists of four runners. In a relay race, a runner runs a specified distance, then passes a baton to a teammate in a so-called exchange zone. The baton is so pivotal as it needs to be passed seamlessly and quickly to prevent time loss. At the end of the race, the team to run the fastest from start to finish wins and gets to celebrate their victory.

Not only are super enamelled aluminium winding wires races a ton of fun, they also provide important lessons in teamwork and good sportsmanship. Working together as runners teaches who can best help whom and how to celebrate as one when success occurs. These races build essential skills such as strength, speed, and stamina. They provide an opportunity for competitors of the sport to show off their running skills and race against other runners who share their passion for running. In addition to that, relay races instill valuable life skills like teamwork, cooperation, and perseverance, which come in handy in many areas.

Stay in your lane – Each runner is assigned an area they run stagnant to then loop and cross when they complete their leg. Practice handing the baton in this domain so you make it transition seamlessly.

Look at other runners — Runners must always notice the runners ahead and their teammates. This helps them keep a decent pace and also allows them to pass their competitors whenever possible.

The runners need a few, but very important, items to run relay races: up-to-date running shoes, comfy outfits and lots of practice. They like to have a firm grasp of the rules of the race and how to work as a team. Relay races vary in distance and format, and come with specific rules for baton handoff and designated exchange zones. It is crucial to know and follow these rules as not doing so could result in the participant being non-compliant to the race itself. All types of relays runners should dedicate time to work on their speed and baton-passing techniques individually and as a team.

Inspired by a partner, relay races drive athletes to break limits, chase medals, and claim glory. These impressive accomplishments require a great deal of effort, time, and consistent practice to be reached, however, if maintained with determination and perseverance, they can be attained.

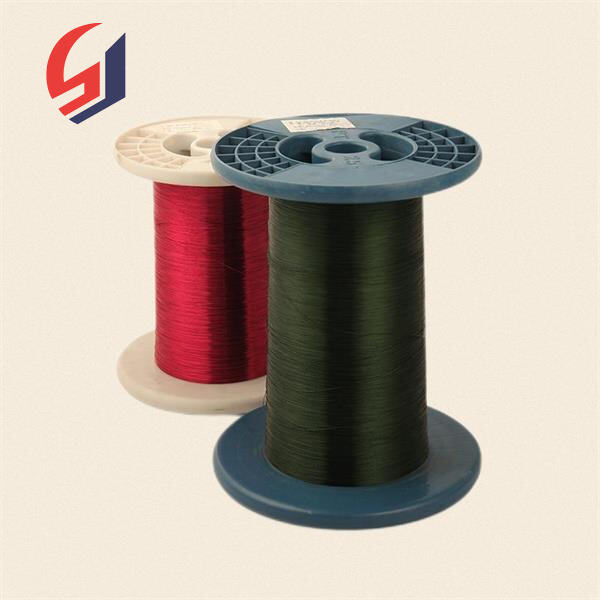

The quality is the main aspect of enameled copper wire. The factory undergoes many quality checks to make sure the quality of the products is in line with international standards and meet customer expectations. (1) Raw materials control from high-purity copper to top quality insulation lacquer, all raw materials undergo strict screening to ensure their performance is stable. 2.) Monitoring of the entire process. From wire drawing through to the process of enameling, each stage of production is subjected strict tests, including electrical performance as well as insulation voltage withstand and tensile tests to guarantee the reliability. (3) Complete certification Quality factories generally have the ability to pass ISO 9001 quality management system certification, as well as UL safety certification. SGS certification to increase the confidence of customers.

Our wire factories that are enameled ensure efficient delivery of products worldwide thanks to the latest manufacturing technology and rigorous quality control. In collaboration with our logistics partners in the world we can create customized logistics solutions to meet the specific needs of different customers. Our global network of delivery partners includes key ports to ensure the goods arrive at their destination quickly and safely. Sales staff at our company also offer online tracking services that keep our customers up-to-date on the progress of their shipments, improving supply chain transparency.

Our factory is able to customize products to meet the requirements of the customers. We also provide complete support after sales. Multiple specifications: Our factory is able to produce enameled wires that meet a broad variety of specifications, which include different diameters of wire, enamel thicknesses, temperatures, and insulation ratings to suit various situations.

Enamel copper wire factories can make high-quality products at an affordable cost because of their production capacity on a large scale. 1.) Production in mass: The manufacturing facility can quickly respond to large orders, and ensure timely delivery. (2) Cost reduction. By improving the process of production and equipment factories are capable of reducing the amount of waste produced, boost output, and cut down on unit expenses and allow customers to get a better price.