Owning a car, or any kind of vehicle with an engine, you well know how well that engine needs to work. A well-oiled machine protects you and gets you from Point A to Point B. WIRING IN THE ENGINE BAY (A MAJOR COMPONENT OF YOUR ENGINE THAT CONTROLS HOW WELL IT RUNS) If the wiring is well done, then it can do wonders for your engine.

If you really want to kick your engine harnesses up a notch for bolstered performance, look no further than Shenzhou Cable. Engine wiring upgrade is a wise move in that it is supposed to enhance the electrical accessories in your vehicle. The best way to deliver power to the various systems in the vehicle so they all work properly is good wiring.

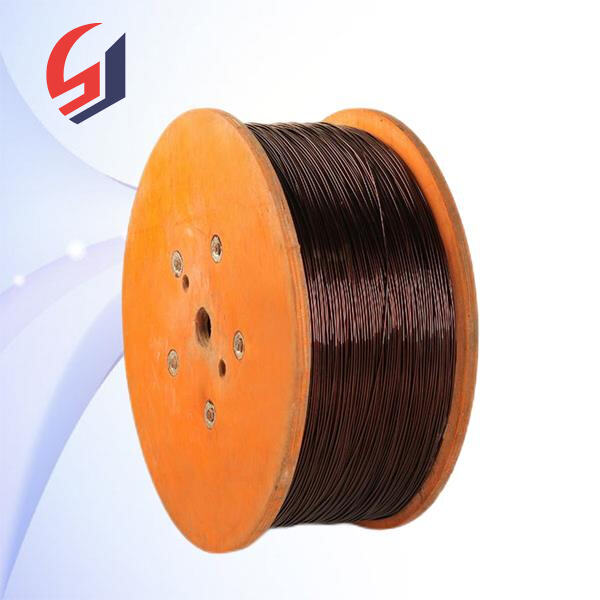

Positive cables and wiring in the engine bay connect all of your car's essential electric components. At first, this system can seem complex and overwhelming — but it doesn’t need to be. With help from Shenzhou Cable, you can make sense of your aluminum enameled wire much more easily. All you need to know is some basic information about its working mechanism and which parts are there.

These components include the battery that gives power to the car, the alternator that keeps the battery charged, the starter motor that starts the engine, the spark plugs which ignite the fuel, coils which help in the ignition process, and sensors that monitor the various functions in the engine. Familiarizing with these segments will be useful for comprehending how the engine wiring system functions cohesivelys with each segment.

Good wiring is vital to your engine bay because it allows everything to work properly and safely. Car engine are known to have very high temperature with vibrations and so many other things, it is very important that you use right tools and materials. From the high-quality materials they use to make wiring solutions, Shenzhou Cable ensures the safety of your vehicle with their wiring solutions.

This will be a very clever step for anyone who wants to boost their car's performance with the wiring of the engine bay. But it must be realized that beginners should first take the time to learn something before trying to get their hands dirty.

Dead Battery: If the car won’t even start or there is absolutely no power, the first thing to check is the battery. This is especially true if the battery is completely dead and it's time to give the car a jump, or replace the battery with a new one.

Modern production technology and strict quality control procedures in our enameled-wire manufacturing facilities allow us to provide products with speed across the globe. In collaboration with our logistics partners in the world we are able to offer customized logistics solutions that meet the specific needs of our customers. Our global network of delivery partners includes important ports to ensure that the products reach their destinations quickly and safely. Our sales team also offers online tracking solutions that keep our customers up-to-date on the status of their shipment and improves transparency in the supply chain.

Copper wire factories that are enamel can produce high-quality products at a lower price due to their scale production capability. (1) Mass production: The factory is able to respond quickly to the needs of large orders, while at the same time ensure the timeliness of delivery. (2) Cost reduction. Through optimizing the production process and equipment, the factory is capable of reducing waste, increase output, and cut down on unit expenses which allows customers to be more competitive in their prices.

The high-quality of enameled copper is of paramount importance. The manufacturing facility goes through a variety of quality control procedures to ensure that the product meets standards of international quality and meet the customer's requirements. (1) Control of raw materials from pure copper to premium insulating lacquer, the raw products undergo rigorous screening to ensure their performance is stable. 2.) Whole-process monitoring. From wire drawing to enameling, every stage of production is subjected strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure quality and safety. In order to increase customer confidence, quality factories are usually certified by ISO 9001 for their quality management system and UL Safety certification.

Our enameled wire factory can customize the products according to customer's special requirements and also provide full after-sales support. Diversified specifications: The factory can produce enameled wires in a wide selection of specifications. This includes different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of application scenarios.