Water cars operate as if they were a magic trick. They have a special pump that works wonders on the water. These cars convert water into power rather than gasoline like the majority of cars. Here’s what happens: the water enters the car engine and gets heated. When the water gets super hot, it becomes steam. That steam is what actually powers the car to move - like a train, but cooler!

Water cars manufacturer have a bigger dream to achieve. They want to contribute to caring for our planet. Regular cars burn gas that can pollute the air and make it yucky. But water cars are different. They use clean water while doing so, that does not hurt the earth. That translates to less smoke in the air and a happier, healthier planet for all.

Quite a fascinating tale the water cars tale is. [Related: You are about to learn that water can be used to fuel a car a long time ago.] But this would not be the case — it would be many, many years before water cars were something real, something that people could actually drive. And now they are as you have loads of brainiac fellows around the world are toiling their butts off in the effort to make their water cars better and cooler.

With so many water car patents, you might want to find out how water cars really work? Let's look inside! That would have its own special pump which does something very special. This pump draws in water and into the car's engine. Then the water heats enough to become steam. Steam has a lot of force, and that energy pushes the car forward. A battery helps ensure all this keeps humming along, much like the way a heart helps keep a body operating.

There are many good reasons to have water cars. At sea, water is ubiquitous, and it doesn’t cost as much as gas. Which means you could get a similar experience without breaking the bank behind the wheel. Water cars also help keep our planet clean and healthy.

Companies such as Shenzhou Cable are working hard to production of water cars for everyone. They are designing vehicles that are Earth-friendly and easy to drive. These clever inventors are the superheroes of the environment!

Imagine a world where the cars you operate do not pollute the air. If you can picture it, it means driving a car, which uses something as common as water for running. Which is exactly what water cars are all about! They inspire us to do wonderful things to help our planet.”

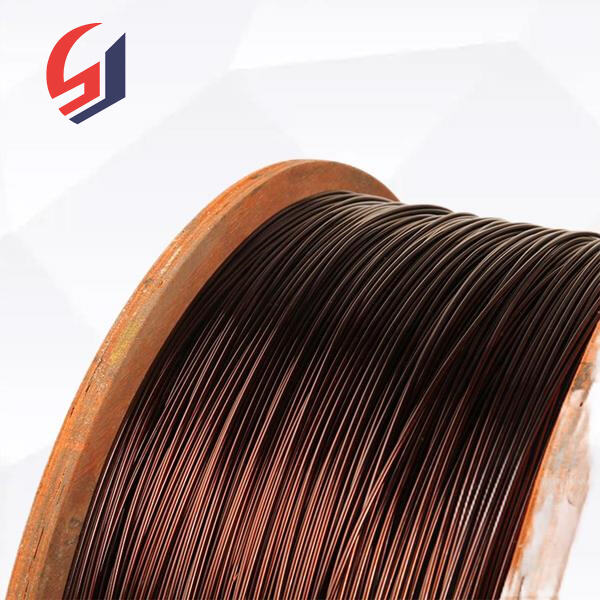

The quality of enameled copper is of paramount importance. The factory goes through numerous quality inspection stages to ensure the products are up to standards set by international standards and satisfy customer requirements. (1) Control of raw material Starting from pure copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure stability. 2) Whole-process monitoring. From wire drawing through to enameling, every stage of production goes through strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure high-quality and reliability. To improve the trust of customers, quality factories are usually certified with ISO 9001 for their quality management system as well as UL safety certification.

Modern production technology and strict quality control procedures in our enameled-wire factories enable us to provide products with speed across the globe. Through close collaboration with our logistics partners in the world, we are able to provide tailored logistics solutions to satisfy the needs of various customers. Our global delivery network is comprised of key ports to ensure products arrive at their destination quickly and safely. Our sales team also offers online tracking services that keep our customers up-to-date on the status of their shipments increasing transparency of supply chain.

Our enameled wire factory is able of customizing products to meet customers' particular requirements. They also provide complete after-sales service. Diversified specifications: The factory is able to produce enameled wires that meet a broad variety of specifications, which include various wire diameters, enamel thicknesses, temperature ratings, and insulation ratings to fit a variety different applications.

Copper wire factories that are enamel can produce high-quality products at cheaper prices due to their scale production capability. (1) Mass production: The factory is able to react quickly to the demands of large orders and at the same time ensure that the delivery time is on time. (2) Cost reduction through a more efficient production and optimizing equipment factories can cut down on consumption and increase the rate of output, thus reducing unit cost and giving customers more competitive cost.