Let's start with copper wire. Generally, this kind of wire is being utilized for several years in electric floor wiring. One of its best features is it lets electricity pass through it extremely well. This is what is known as being highly conductive. This is why copper wire is a very efficient way to transport electricity. It is also very durable and will last many years without deteriorating. This is the reason that a lot of individuals prefer copper wire for projects that want to be sturdy and tough. On the downside, copper wire is relatively expensive. As this more expensive rate can put it out of reach for some, particularly if working to a budget.

And now, we discuss CCA wire. CCA⇒Copper Clad Aluminum, which indicates that this cable is formed from a blend of copper and aluminum. One of the primary reasons why CCA wire is preferred by many people is that it is relatively less expensive than pure copper wire. This is why it is a cost-saving alternative for your project. CCA wire is also much lighter than copper wire, which may be considerably useful for some kinds of projects where weight is a crucial contest. However, CCA wire is not as good of an electrical conductor as copper wire. In the long run, this means that CCA wire does not function as effectively for projects in which a consistent and safe flow of electricity is needed.

You need to be aware of your project needs when choosing between CCA and copper wire. In one of your projects if you need a wire which is a good conductor of electricity having longer durability then copper wire may be the best option for you. It retains the highest level of trust, at least in case of critical projects. On the other hand, if you need a wire that is lighter and less expensive—maybe for a small project or one that doesn’t have a lot of demands— then CCA wire might be the right choice for you.

Comparing CCA and copper wire can be very useful because it helps you assess which one of the two forms offers you the best option according to your individual requirements. Explanation: When it comes to conductors, copper wire is the number one choice. It has a conductivity rating of 100% so it transmits electricity, energy, as freely as possible. Whereas, CCA wire only has a conductivity rating of 60%. It has a lower rating, which means it won't allow electricity to flow as easily, which is why copper wire is a more dependable option for numerous types of projects.

As far as the cost is concerned, CCA wire is definitely the less expensive choice. It is also cheaper to produce than wire made entirely of copper due to the combination of copper and aluminum. But it is important to note that CCA wire is usually not as durable and will not last as long as copper wire. While this may appear to save you money now, however, it may end up being the reason you will need to replace it sooner, costing much more money down the road.

The use of CCA and copper wire also must be considered from an environmental perspective. Copper wire is a natural resource that is produced from the earth and also can be recycled. Copper wire is therefore a more environmentally friendly choice for those who are concerned about the environment. CAC wire, on the other hand, is harder to recycle because the aluminum and copper have been mixed together. So that's why it's much harder to separate them, hence not as eco-friendly.

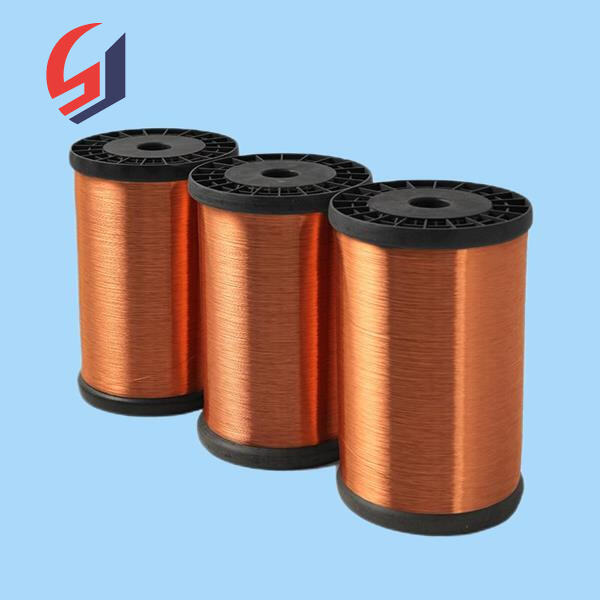

Shenzhou Cable take the impact which our products have on the environment very seriously. We feel it is important to consider the ways that the materials we use can impact the earth for generations to come. This is the reason that we provide a variety of copper wire items that are both extremely conductive and long-term. Although if you require a cheaper solution we offer CCA wire products as well.

The modern production methods and strict quality control procedures in our enameled-wire manufacturing facilities allow us to efficiently deliver our products throughout the world. By working closely with our international logistics partners we can offer customized logistics solutions that meet the specific needs of our customers. Our delivery network in the world covers important ports, ensuring that goods reach their destinations promptly and safely. Sales staff at our company also offer online tracking solutions that keep our customers updated on the status of their shipment and improves transparency in the supply chain.

Copper wire manufacturers in enamel can produce high-quality products at cheaper prices due to their production capacity on a large scale. 1.) Mass production: The company can quickly respond to large orders, and ensure the timely delivery. (2) Reduced costs through an efficient manufacturing process and optimization of equipment, the factory can reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive cost.

The high-quality of enameled copper is of paramount importance. The manufacturing facility goes through a variety of quality control procedures to ensure that the product meets standards of international quality and meet the customer's requirements. (1) Control of raw materials from pure copper to premium insulating lacquer, the raw products undergo rigorous screening to ensure their performance is stable. 2.) Whole-process monitoring. From wire drawing to enameling, every stage of production is subjected strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure quality and safety. In order to increase customer confidence, quality factories are usually certified by ISO 9001 for their quality management system and UL Safety certification.

Our factory is able to customize products to meet the requirements of the customers. We also provide complete support after sales. Multiple specifications: Our factory is able to produce enameled wires that meet a broad variety of specifications, which include different diameters of wire, enamel thicknesses, temperatures, and insulation ratings to suit various situations.