Having choice when it comes time for wiring can be useful for an electrical project. Solid wire and CCA wire, which is short for copper clad aluminum, are two types of wire people commonly use. Introducing the differences between the two types of wiring can help you make the best decision for your needs. So let's break that down and figure out if these wiring options are worthy of your money.

The first consideration is whether the choice of solid copper or CCA wiring is a good investment of your money. In general, solid copper wiring is more expensive than CCA wiring. But there’s a solid reason for this. So, pure copper conducts electricity far better than CCA. This means that pure copper can conduct more electricity as smoothly before it overheats. It does not heat up so much, which reduces the risk of overheating or fires. For those who value safety above all else, using solid copper wiring may well be the best investment you make.

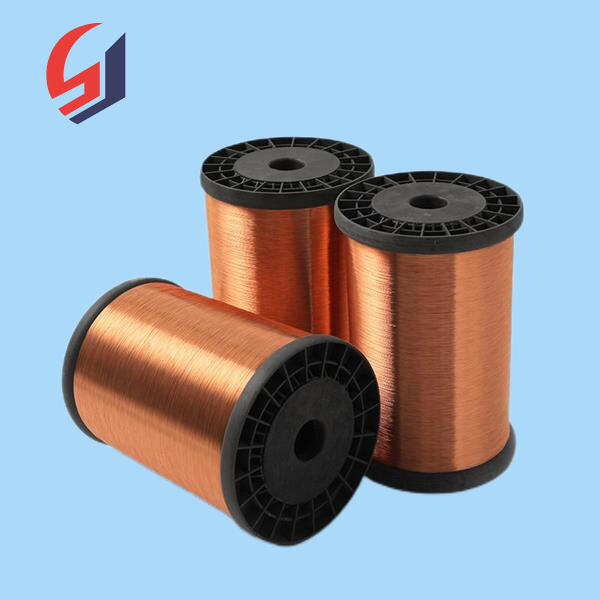

Solid copper wiring consists of 100% copper. This material can effectively conduct electrical current and is thus used in numerous electrical systems. Some of the benefits of solid copper wiring are as follows:

Upper right image: Each solid copper wire is built to last longer. There is also less chance of wear and tear causing it to break down, so it can keep your electricals working perfectly for much longer.

Actually CCA wiring is slightly different. There is aluminum inside, and thin layer of copper around. Initially, CCA wiring is less expensive than solid copper, but this comes with certain significant compromises. Here are the key problems with CCA wiring:

So which is right for you when you are thinking about what power cabling is best to use for your electrical needs really depends on what you want and what your budget is. If you think solid copper wiring is an expensive option, your right, up front. But it is usually a more secure and steadfast option, particularly to critical tasks where a failure can cause a threatening state of affairs. CCA wiring, on the contrary, is relatively cost effective for smaller projects where budget is tight and safety is not a key consideration.

Ultimately, whether to use solid copper or CCA wiring is going to be a decision based on your budget, the type of electrical system in question, and what is most important to you. So, if your needs are in a wiring option that is termed to be high performing, long lasting, and extremely safe, then solid copper is for sure the more superior option for you. On the other hand, if you are trying to cut costs and are working on a nonessential project, CCA wiring might be more attractive.

The high-quality of enameled wire copper is of paramount importance. The manufacturing facility goes through a variety of quality checks to make sure the quality of the products is in line with standards set by international standards and satisfy customer needs. (1) Control of raw materials From pure copper, to high quality insulation lacquer, all raw materials undergo strict screening to ensure stable performance. (2) Continuous monitoring of the process: From wire drawing to enameling, each stage of production goes through rigorous testing including tensile strength along with electrical and insulation voltage withstand tests, to ensure the quality of the product. In order to increase customer confidence Quality factories are typically certified with ISO 9001 for their quality management system, as well as UL Safety certification.

Copper wire manufacturers in enamel can produce high-quality products at cheaper prices due to their production capacity on a large scale. 1.) Mass production: The company can quickly respond to large orders, and ensure the timely delivery. (2) Reduced costs through an efficient manufacturing process and optimization of equipment, the factory can reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive cost.

The modern production methods and strict quality control procedures in our enameled-wire manufacturing facilities allow us to efficiently deliver our products throughout the world. By working closely with our international logistics partners we can offer customized logistics solutions that meet the specific needs of our customers. Our delivery network in the world covers important ports, ensuring that goods reach their destinations promptly and safely. Sales staff at our company also offer online tracking solutions that keep our customers updated on the status of their shipment and improves transparency in the supply chain.

Our enameled wire factory can customize the products according to customer's special requirements and also provide full after-sales support. Diversified specifications: The factory can produce enameled wires in a wide selection of specifications. This includes different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of application scenarios.