One of the best ways to get your Ford 351W build to perform what it can though is to utilize connection quality and swap over to Ford Racing spark plug wires. If someone is good enough to carry out these repairs, then when applying they will use your special engine wires. You feel the difference in your engine performance right after getting these wires upgraded.

Well, what is it that makes Ford Racing spark plug wires stand out from the competition? First, they are constructed with durable materials that can withstand a lot of power. They are high grade silicone insulated which means they are heat and damage resistant as well. This allows the wires to last longer and function better. Within the wires rest robust metal cores that actually fight against wear and tear, allowing them to suit the capability of an intense motor.

One of the most important components in your engine is the ignition system. It helps start your engine and keeps it running smoothly. This can be much improved with the help of Ford Racing spark plug wires. These wires make electricity flow more smoothly that will cause your spark plugs to fire regularly. Well-functioning spark plugs mean smoother engine operation, less fuel use, and better overall performance. When you switch to these wires, you’ll notice far greater power and response in your car.

If you use a muscle car and performance in your usage, you are well aware that every detail matters. That is why upgrading your spark plug wires is one of the best things you can do. Ford Racing Spark Plug wires make sure that it is burning more fuel than before and can be observed in statistics in a lot of ways like acceleration and top speed and feel. These are performance wires for better engines, so they can add on the power and last longer, even when the engine is being pushed hard.

If you’ve already spent money on other Ford Racing ignition parts, it’s a no-brainer to add their spark plug wires. These wires are engineered to optimize performance with other Ford Racing parts, ensuring proper fitment with your engine’s ignition system. With this match, your engine will perform better and be more reliable. You know your engine will run better when it's running together.

All parts play a role in extracting the most performance from your engine — including your spark plug wires. For example, you can expect more than a few upgrades in your engine’s performance by moving up to Ford Racing spark plug wires. Yadi yada, including improved acceleration, faster throttle response and a noticeable increase in power output. Additionally, you can have more peace of mind knowing you’re working with well-made wires that were designed with your Ford 351W engine in mind before you ever started your project.

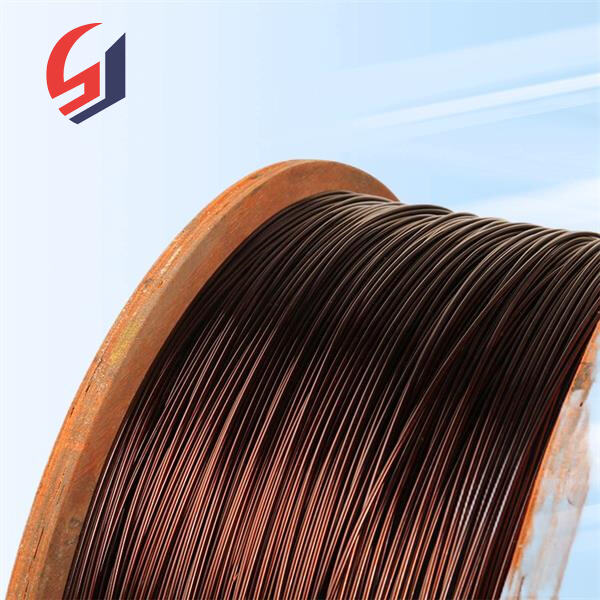

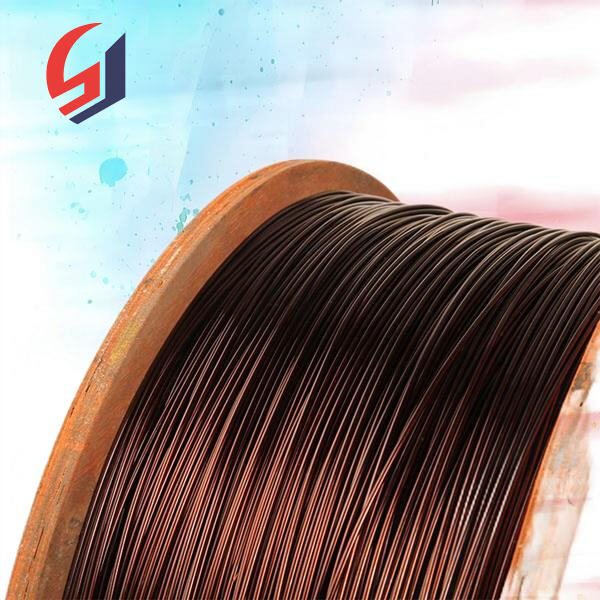

Copper wire factories with enamel coating can create high-quality products at an affordable cost because of their scale production capability. (1) Mass production: The factory is able to respond quickly to the needs of large orders, while at the same time guaranteeing the speed of delivery. (2) Reduced costs through an efficient production process and equipment optimization manufacturing, factories can decrease production waste and improve output and reduce unit cost and giving customers more competitive price.

Our enameled wire factory can customize the products according to customer's special requirements and also provide full after-sales support. Diversified specifications: The factory can produce enameled wires in a wide selection of specifications. This includes different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of application scenarios.

Modern production technology and strict quality control procedures in our enameled-wire manufacturing facilities allow us to provide products with speed across the globe. In collaboration with our logistics partners in the world we are able to offer customized logistics solutions that meet the specific needs of our customers. Our global network of delivery partners includes important ports to ensure that the products reach their destinations quickly and safely. Our sales team also offers online tracking solutions that keep our customers up-to-date on the status of their shipment and improves transparency in the supply chain.

The quality is the main component of enameled wire. The factory goes through numerous levels of quality inspections to ensure that the products are in compliance with the requirements of international standards and customers. (1) Control of raw materials from pure copper, to high quality insulating lacquer, the raw materials are subjected to rigorous screening in order to ensure stable performance. 2.) Whole-process monitoring. From the beginning of wire drawing to the process of enameling, each stage of production is subject to strict tests, including electrical performance as well as the withstand of insulation voltage and tensile tests to ensure reliability. (3) Full certification: Quality factories usually have the ability to pass ISO 9001 quality management system certification as well as UL safety certification, SGS certification to enhance the confidence of customers.