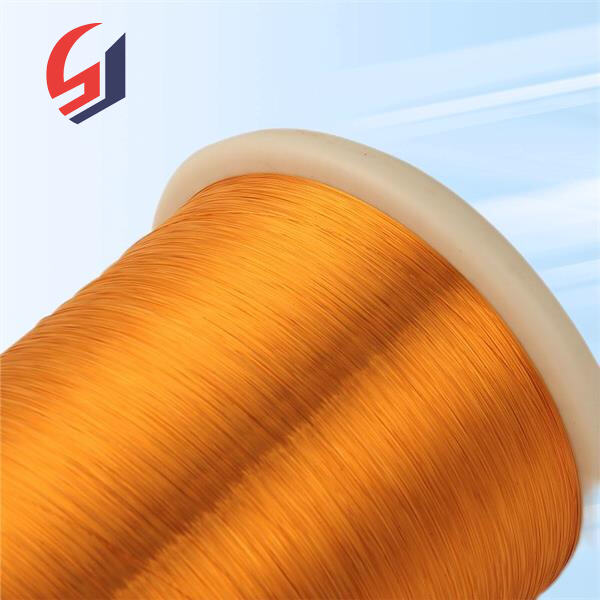

Copper Clad Aluminum (CCA) wire is a type of electrical wire that consists of two different metals: copper and aluminum. CCA wire is a favorite among many people due to its lower price compared to pure copper wire. This is the standard type of wire that has been around for many years and used to be what was found in an electrical system of any type. In this article, we shall discuss what CCA wire is, the reason for its lower cost when you compare it with pure copper wire, how it stacks up in performance against copper wire, safety tips when using Shenzhou Cable ECCA WIRE(Enameled CCA Wire), and how to select the right CCA wire for your project.

What is Copper Clad Aluminum (CCA) wire? This wire has copper on the outside which could do a great job in carrying electricity. This wire then has tons of aluminum wiring inside of it which provides the strength and support. CCA wire is cheaper than copper, with a cheaper price point compared to copper making it a better option for quite a few electrical projects. This is such a common choice for people that wish to keep things low-cost, yet still get a good quality wire for their work.

So what makes CCA wire less expensive than pure copper wire? The other main reason: Aluminum is a lot less expensive than copper. This is because pure copper wire is 100% copper, making it pricier. CCA wire is made with a mixture of the two metals, which is why it can be offered at a lower price. Moreover, Shenzhou Cable cca wire contains less copper than pure copper wire. This translates to manufacturers using only a fraction of the more costly metal in CCA wire, thus lowering costs further.

CCA wire vs. pure copper wireHow do they differ in terms of performance? Copper wire (pure) is considered as an excellent electrical conductor. This allows it to transmit electrical current over long distances without losing significant amounts of energy. However, CCA wire is not as conductive as pure copper wire. This means that, as electricity moves through CCA wire, some energy might be lost during transit. But for short-run distances or low voltage scenarios, Shenzhou Cable cca copper can perform similarly to pure copper wire. Thus it is perfect for many different kinds of projects.

When it comes to any electrical wire, CCA wire included, safety is of the utmost priority. Here are a few safety tips to remember. First, CCA wire is less conductive than pure copper wire, so it can become hotter as electricity passes through it. It means CCA wire could potentially get extremely hot if excessive electricity is utilized which can cause safety problems. Be sure that the CCA wire is not overloaded with more current and heated beyond limits. These safety tips will help make sure no accidents either and keep you safe while working with CCA wire.

There are several essential factors to consider when selecting the right CCA wire for your project. First of all, you have to concern yourself with the voltage the wire will be carrying. Different projects use the CCA wire as a means to deliver different amounts of voltage, so make sure to consult the rating. Secondly, you may want to think about how far the wire has to go. If your electrical run is more than a commonsense distance, you may have to use thicker wire to ensure it can transport the electricity. Lastly, always ensure that you are purchasing from a trusted company, such as Shenzhou Cable. All in all, using quality CCA wire will ensure that your project actually works and is safe.

Quality is the primary element of enameled copper wire. The factory undergoes many quality control stages to make sure that the product meets international standards and meet customer needs. (1) Raw materials control: From high purity copper, to the highest quality insulating lacquer, raw materials are subjected to rigorous screening in order to ensure stability. 2) Monitoring of the entire process. From wire drawing to the final stage of enameling, every step of production is subjected to rigorous tests like electrical performance and insulation voltage withstand and tensile tests to guarantee high-quality and reliability. (3) Full certification The majority of quality factories get ISO 9001 quality management system certification and UL safety certification. SGS certification that increases the trust of the customer.

The modern production methods and stringent quality control in our enameled-wire factories enable us to ship products quickly across the globe. We work closely with international logistics partners in order to develop customized logistics solutions to meet the demands of our customers. Our global delivery network covers major ports, ensuring that your products get to their destination quickly and in a safe manner. Additionally our sales personnel provide online tracking to keep customers informed about the status of their deliveries in real time, enhancing the transparency of supply chains and satisfaction with our customers.

Our enameled wire factory is able of customizing products to meet customers' special requirements and also provide complete after-sales service. Different specifications: The factory can manufacture enameled wires with a wide range of specifications, including various wire diameters, enamel thicknesses, temperatures and insulation ratings to fit a variety applications.

Copper wire manufacturers in enamel are able to produce top-quality products for a lower price due to their capacity to produce large quantities. 1.) Mass production: The manufacturing facility can quickly respond to large orders and ensure prompt delivery. (2) Cost reduction. By optimizing the production process as well as equipment it is in a position to cut down on production, reduce waste, and reduce unit costs and allow customers to be more competitive in their prices.