Amahlelo nokuthi kungenziwe noma akungenziwe ngokusebenzisa i-Copper Clad Aluminum

Ngokwesibungu, i-copper clad aluminum iyishona ngenxa yalokho. Yinto ephakamisekileyo, ukuhlala kwezilimi zomthetho wokusuka kwezinkathalo ezindala nokuxhasa, lokhu olukhoyo lwenqanawe. Ukuxhasa kukufundiswa ngokubonisa amalume ngazo nezinye izinto namandla nokuxhumana nokuxhasa, okugcina emva kokuthi ukuba icopper clad aluminum ihlale kuxhasa, akwazi ukususa inqanawe ngokuphi ingxenyeni. Ukuba umsebenzi wakho uwusetyenziswa ukuyidalwa kwindawo ekudliwe ngeminyaka eminingi, lokhu liyafuneka ulenzelele xa uvutela leli metal yezimpahla zakho.

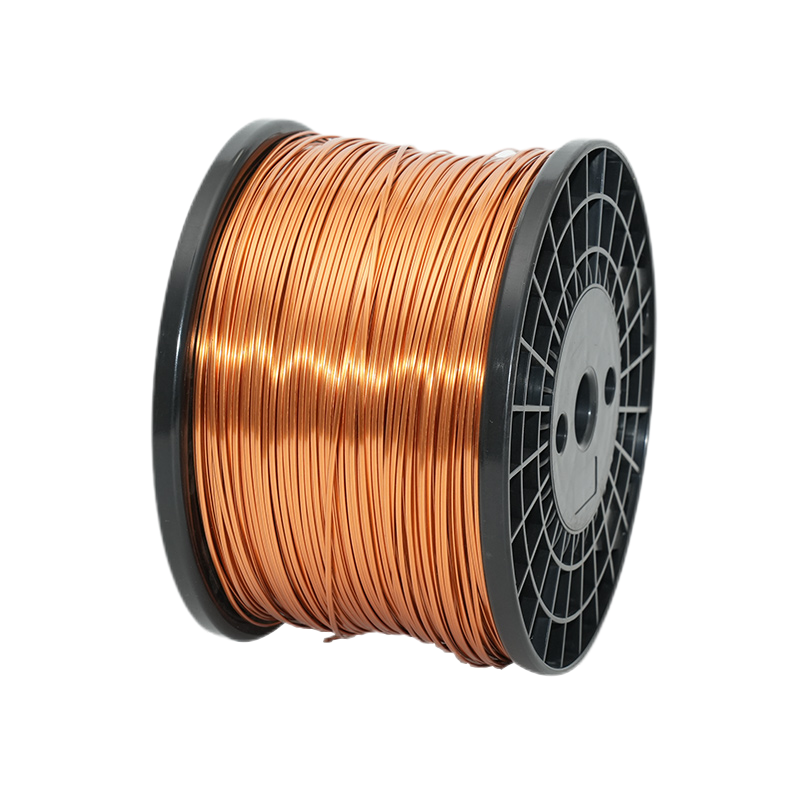

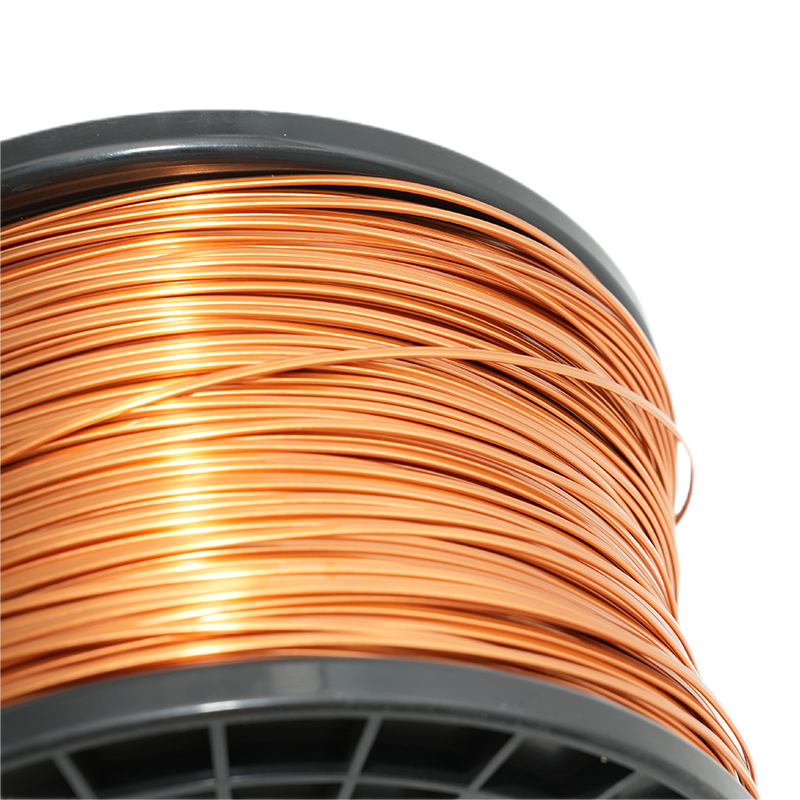

I-Copper coated Aluminum usebenziswayo kakhulu kwi-electricals ngokusebenzisa amandla angaphakathi. Xa i-copper kunye ne-aluminum zikhombisana, bazame ukufakwa imetal elingcede kunye nokuhlala kakhulu kulandelule kwe-copper noma i-aluminum ngaphezu kwaloo. Ngokulandelayo ukufaka kwe-copper clad aluminum kufanelela ukuba kufunekako ukusetshenziswa kwesi-sayili esetshenziswa ngokubanzi. Ukuphawula: Izindlela zisetshenziswa ukuba zihamba ngokubanzi inqanawe ngokubanzi ngendawo engeyiyo. Ukuba zindlela azisetshenziswa ngokuphi na, zizipha noma kuphela ngokushaya, oku kuhluke. Lokhu lenze i-copper clad aluminum ukuba libe lisho.

ZU

ZU