The high frequency transformer is an electrical power conversion device designed to operate above 20 kHz which is a very high frequency for power circuit. At these currents, the electrical current flowing through the transformer coil can heat. This excess heating can result in energy being lost. To avoid this waste of energy, we use custom winding techniques (the way how to wrap wires). Therefore, We wind a thin wire around a core of iron or ferrite. How we wind the wire is very crucial for the O'rash tizimini qabul qilish transformer to work more efficiently and effectively.

High frequency transformer winding where one of the main jobs is to make sure the transformer sends out electrical power as good as possible. To figure out how effectively the transformer is doing its job, we can map the ratio of power output to power input. This comparison gives us the efficiency of the transformer. And so we configure the winding in a manner that minimizes energy loss to improve power transfer. This is accomplished by winding the coil in certain patterns that both shorten the length of the wire and keep it as close to the core of the transformer as possible. This shamol energiyasi generatori makes it easier to train the transformer.

Your electrical system is not like any other, so you need specific to your system transformer. Hence, we need to modify the winding accordingly based on the required application or usage. So, we need to consider various parameters, like the transformer size, the number of turns we give to wrap the coil, and the quality of wire that would be used in the winding.

Due to the increased requirement for high-speed power systems in technology, let us understand why high frequency transformers are gaining more popularity these days. These growing needs necessitate ways to improvise designing the winding of transformers. One novel method is tightly winding the wire around the center. This helps shorten the length of the wire, reducing energy loss. You can also use thinner wire and other things such as layers of insulation in the winding to make the transformer more efficient.

Olivey KeYat Shenzhou kabeliYangi quvvat transformatorida samarali quvvat uzatish uchun transformator o'rashining ahamiyati. Mutaxassis muhandislarimiz maksimal darajada oshirish uchun murakkab texnikadan foydalanadilar super emallangan alyuminiy o'rash simlari mijozlar talablariga muvofiq dizayn. Ushbu transformatorlar bozorda mavjud bo'lgan eng yaxshi materiallardan foydalangan holda qurilgan.

Eng so'nggi ishlab chiqarish texnikasi va sirlangan simli ishlab chiqarish korxonalarimizdagi qat'iy sifat nazorati bizga mahsulotimizni butun dunyo bo'ylab samarali etkazib berish imkonini beradi. Dunyodagi logistika bo'yicha hamkorlarimiz bilan yaqin hamkorlik orqali biz turli mijozlarning o'ziga xos talablarini bajarish uchun moslashtirilgan logistika echimlarini yaratishga qodirmiz. Bizning global yetkazib berish tarmog'imiz mahsulotlarning o'z manzillariga tez va xavfsiz yetib borishini ta'minlaydigan yirik portlarni o'z ichiga oladi. Bundan tashqari, bizning savdo vakillarimiz mijozlarni real vaqt rejimida yetkazib berish holati to‘g‘risida xabardor qilish, ta’minot zanjiri shaffofligini va mijozlar ehtiyojini qondirish uchun onlayn kuzatuvni ta’minlaydi.

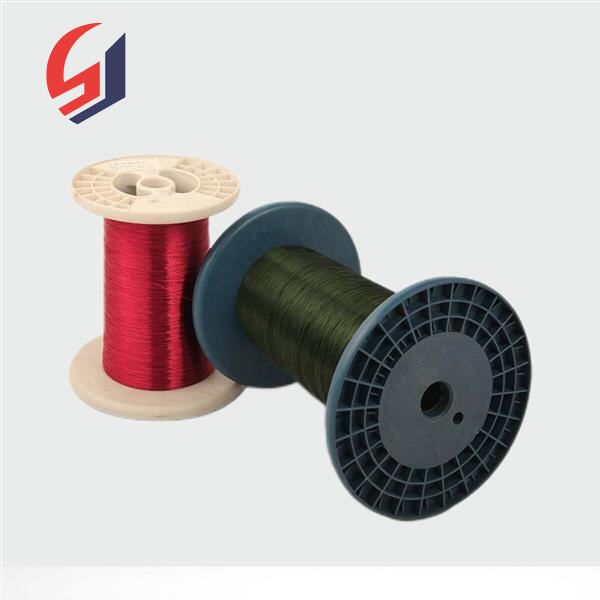

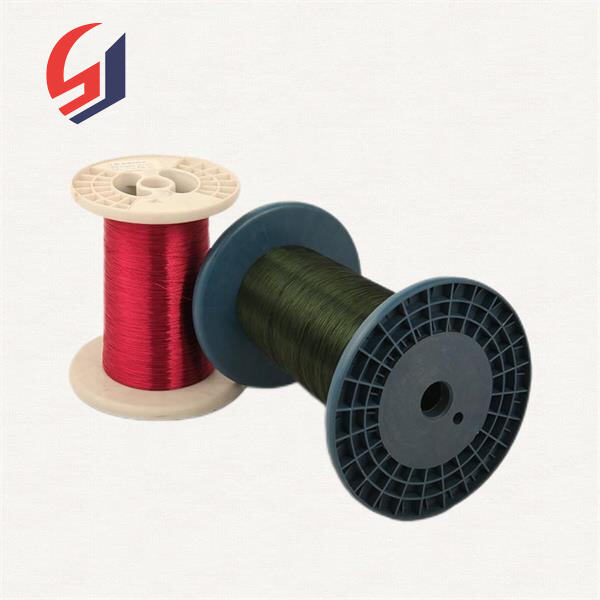

Sifat sirlangan mis simning asosiy komponentidir. Zavod mahsulotlarning xalqaro standartlarga, shuningdek, mijozlar talablariga muvofiqligini ta'minlash uchun sifatni tekshirishning ko'plab bosqichlaridan o'tadi. (1) Xom ashyo nazorati: yuqori toza misdan yuqori sifatli izolyatsiya lakiga qadar, xom ashyo barqarorligini ta'minlash uchun yaxshilab tekshiriladi. 2.) Butun jarayon davomida monitoring. Tel chizish boshidan emalga qadar ishlab chiqarishning har bir bosqichi ishonchliligini ta'minlash uchun elektr quvvati, shuningdek, izolyatsiya kuchlanishiga chidamliligi va kuchlanish sinovlari kabi qattiq sinovlardan o'tadi. Mijozlarning ishonchini oshirish uchun yuqori sifatli ishlab chiqarish korxonalari odatda sifat menejmenti tizimi va UL xavfsizlik sertifikati uchun ISO 9001 sertifikatiga ega.

Ko'lamli ishlab chiqarish quvvati sirlangan mis sim ishlab chiqaruvchi zavodlarga yuqori sifatli mahsulotlarni arzon narxlarda taklif qilish imkonini beradi. 1) Ommaviy ishlab chiqarish: zavod katta buyurtmalarga tezda javob bera oladi va o'z vaqtida yetkazib berishni ta'minlaydi. (2) Xarajatlarni kamaytirish. Ishlab chiqarish jarayoni va asbob-uskunalarni optimallashtirish orqali u iste'molni kamaytirishga, ishlab chiqarishni ko'paytirishga va birlik xarajatlarini pasaytirishga qodir, shuning uchun mijozlar yaxshi narxga ega bo'lishlari mumkin.

Emal qilingan sim uchun fabrikamiz mahsulotlarni mijozning maxsus talablariga muvofiq sozlashga qodir. Ular, shuningdek, to'liq sotishdan keyingi xizmatni taqdim etadilar. Biz turli xil texnik xususiyatlarni taklif qilamiz: Kompaniyamiz sim diametrlari, emal qalinligi, harorat ko'rsatkichlari va izolyatsiyalash ko'rsatkichlari kabi turli xil spetsifikatsiyalarda emallangan kabellarni ishlab chiqarishi mumkin.