Alam mo ba na bawat pagbubukas mo ng ilaw sa bahay o pagsasanlang ng telepono, may mga espesyal na kawad na elektriko na lumalaban sa katotohanan upang magbigay ng kuryente sa mga pundasyon mo? Mga kawad na ito ay napaka-importante para sa maayos na operasyon ng lahat. Uri ng mga kawad May maraming uri ng mga kawad, at talaga ang dalawang pinakakomun na uri ay kilala bilang pure copper at CCA. Kaya ano ang pagkakaiba sa dalawang uri ng kawad at alin ang mas mahusay na pagpipilian para sa iyong mga pangangailangan sa elektrisidad? Papaliwanag namin ito sa simpleng salita, kaya maintindihan mo ito tulad ng batang nakapag-aral pa lamang sa ikatlong baitang.

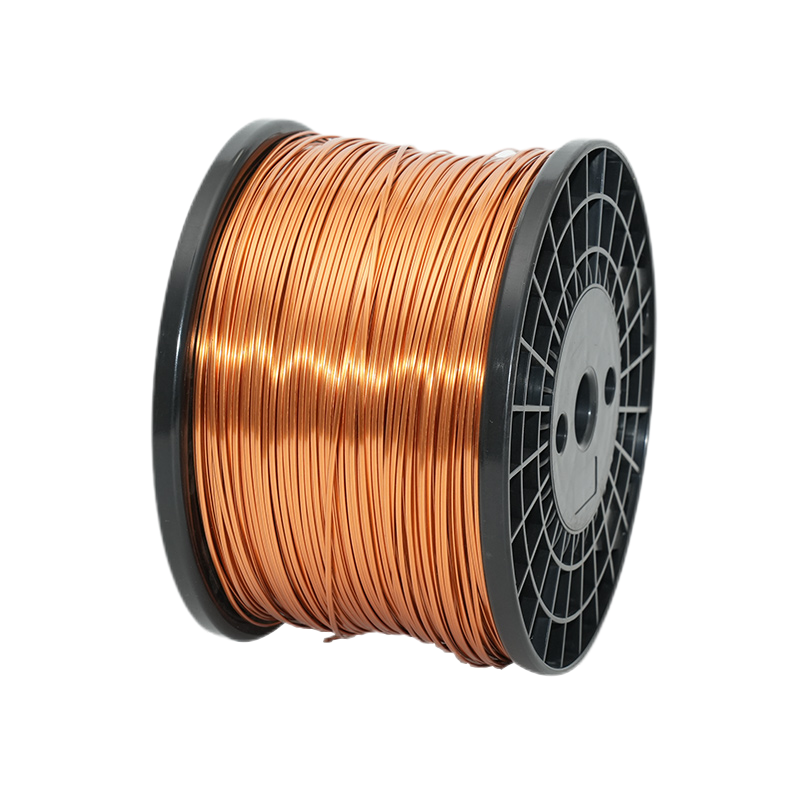

Simulan natin ang mga bulaklak na made sa tambak. Totoo sa kanilang pangalan, ang mga puro na kawad na tambak ay binubuo lamang ng metal na tambak. Ang tambak ay isang napakagandang materyales dahil umiiyak ang elektrisidad sa pamamagitan nito nang mabilis at madali. Ito ay ibig sabihin na gumagawa ng isang napakagandang trabaho ang mga puro na kawad na tambak sa pagpapasa ng mga senyal na elektriko mula sa isang lugar patungo sa isa pa. Partikular na maayos sila para sa mga kagamitan na may mataas na demandang kinakailangan ng maraming enerhiya, tulad ng mga alat pangpwersa, mga sistema ng tunog na nagpe-play ng musika at mga sistema ng video na nagdadala ng pelikula o laruan.

TL

TL