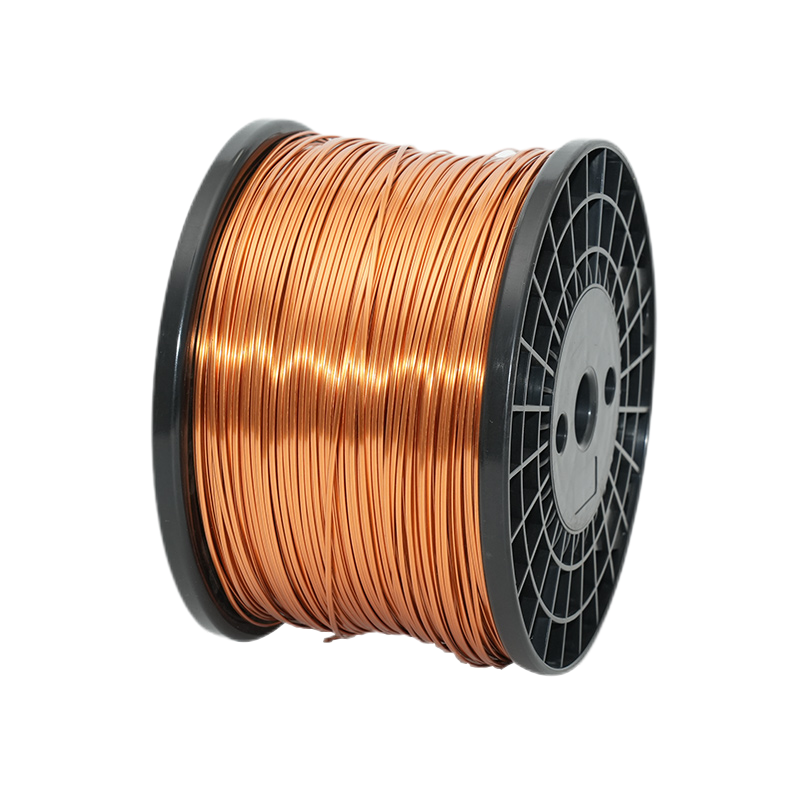

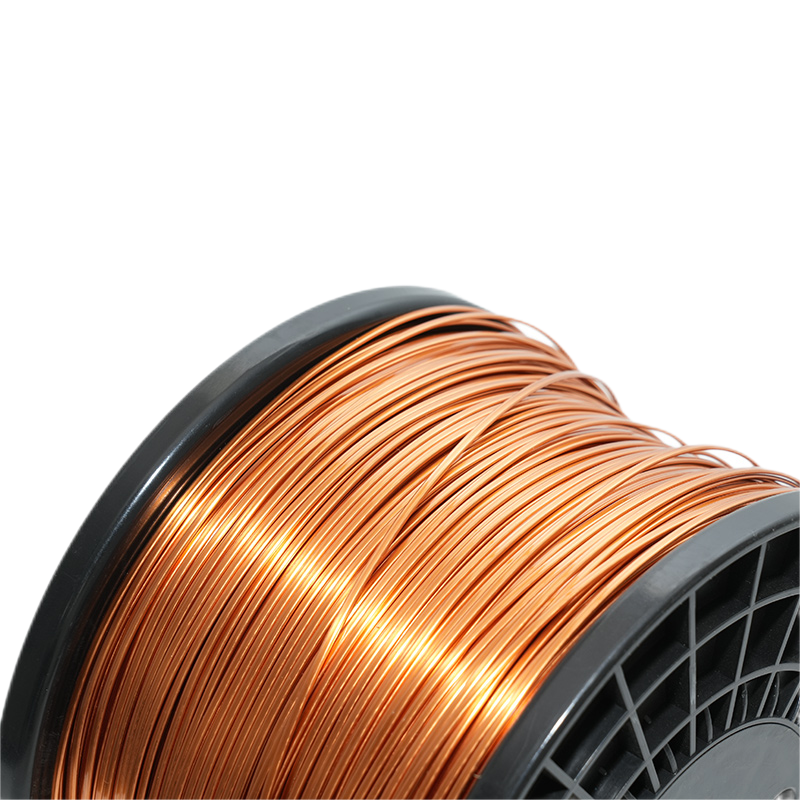

Ang bakal na isa sa mga metal na gagamitin namin sa lahat — sa elektrisidad, sa espasyo ng konstruksyon, sa maraming iba't ibang lugar. Ito ay isang malakas at makapal na metal at isang mahusay na tagapagdala ng kuryente. Dahil sa mga kamangha-manghang katangian na ito, ito ay isang pinilihan para sa maraming proyekto. Sa pangkalahatan, ang liso na bakal ay bilog o obalo, pero ngayon mayroon na tayong tinatawag na aluminum enameled wire , na dinala sa amin sa pamamagitan ng isang kompanya ng Shenzhou Cable.

Isang pangunahing benepisyo ng paggamit ng tinatapong kawad na bakal ay ito ay may mas magandang pagganap kapag kinondukta ang kuryente. Ang anyong flat ay nagbibigay ng higit pang lugar sa kawad, pinapayagan itong kondutahin ang kuryente nang higit makabuluhan. Mahalaga ang trabaho na ito upang panatilihing gumagana ang mga makina at kagamitan nang hindi tumigil. Tulakdin din ng flat wire na maiwasan ang sobrang init habang gumagana. Iisa pang mahalagang operasyon ay panatilihing malamig ang kawad lalo na sa mga makina na may mataas na elektiral na saklaw tulad ng mga motor na elektriko. Ito ang default na pagpipilian ng pagbangon sa P2SD dahil ang init ay kaaway; kung masyadong mainit ang kawad, dadulot ito ng pagbaba sa kalidad at magiging sanhi ng mga problema, kaya't tulakdin ng opsyong ito ang pagsabog ng peligro sa paggawa habang mainit.

TL

TL