Výhody prechodu na vyrovnaný mosačný drôt

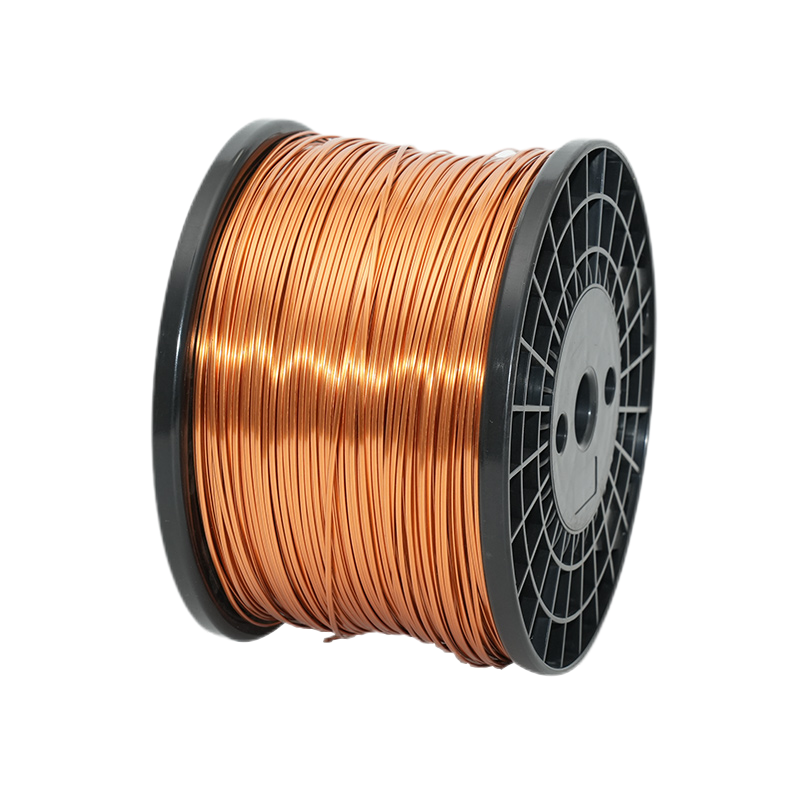

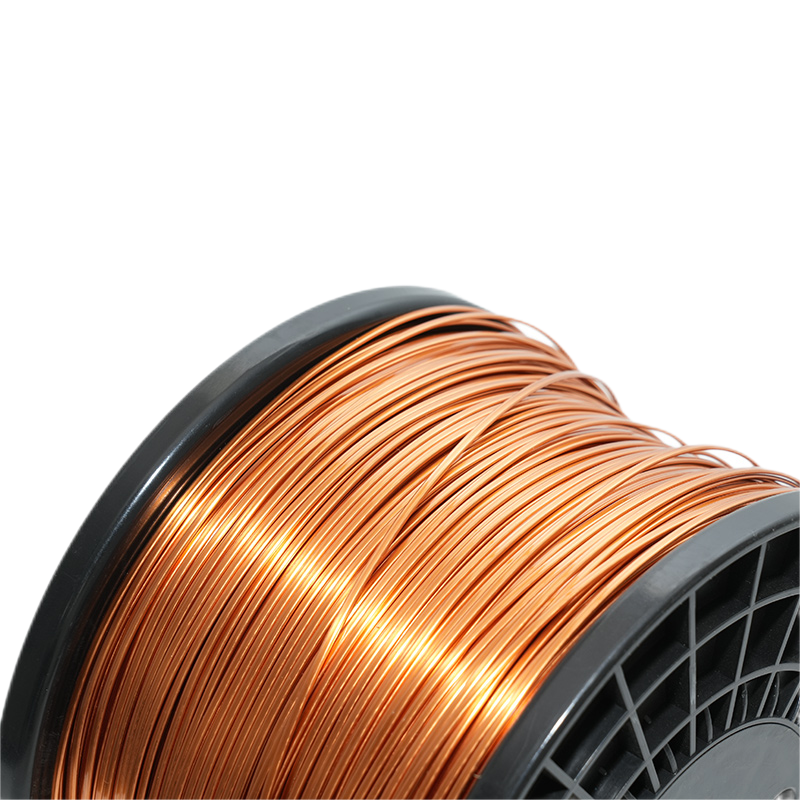

Pločiaty mosazný drôt sa používa v rôznych priemyselných odvetviach, osobitne v úzky priestory. Plochý dizajn umožňuje instalovať drôt v tiahnutých priestoroch, ako sú vnútri elektrických aut a lietadiel. navyše je tiež veľmi efektívny pre elektronické zariadenia, pretože môže znížiť rušivé vplyvy iných signálov. To znamená, že zariadenia môžu fungovať lepšie a spoľahlivejšie.

Plochý mosazný drôt má mnoho použití aj v stavebnom priemysle. Plochý dizajn im umožňuje používať tenšie drôt, čo ne len šetrí peniaze na samotnom drôte, ale tiež uľahčuje a zrýchľuje inštalácie. Je to jedna z príčin, prečo si stavitelia po celom svete vyberajú super emailované hliníkové zavádzacie dráty pre domácnosti aj podniky. Ušetrí im čas a energiu v fáze stavby.

SK

SK