ご存知ですか?自宅のライトを点けたり、スマートフォンを充電したりするたびに、デバイスに電力を供給するために特別な電気配線が働いていることを。これらのワイヤーは、すべての機器がスムーズに動作するためには非常に重要です。ワイヤータイプ さまざまな種類のワイヤーがあり、おそらく最も一般的な2つのタイプは純銅とCCAと呼ばれます。では、この2種類のワイヤーの違いは何でしょうか?そしてどちらが電気のニーズにとってより良い選択なのでしょうか?私たちはそれを簡単に説明しますので、3年生の子供でも理解できるはずです。

では、銅線から始めましょう。その名のとおり、純銅線は銅金属のみで構成されています。銅は電気を素早く簡単に流すことができるので、非常に優れた材料です。これはつまり、純銅線が電気信号を一か所から別の場所へ伝達するのに非常に適しているということです。彼らは特に多くの電力を必要とする高負荷デバイスに適しています。例えば、電動工具や音楽を再生するサウンドシステム、映画やゲームを表示するビデオシステムなどです。

実心銅線が優れている主な理由は、銅がアルミニウムよりもずっと良い電気伝導体であることです。それは、過熱することなくより多くの電気が純粋な銅線を通じて流れることを意味します。熱はワイヤーを損傷したり火災の原因になったりし、それは危険です。高出力用途においては、純銅製のワイヤーが合金ワイヤーよりも安全に多くの電流を運ぶことができるので最適です。銅はまたデータ伝送にも優れており、それが品質が本当に重要となる音響や映像システムで使用される所以です。

純銅線がCCA線よりも長い寿命を持つことは、それらを使用するもう一つの利点です。銅は錆びや腐食に対して非常に強いです。これは、湿った空気、塩水、または環境中の他の有害物質が純銅線の故障を引き起こす可能性が低いことを意味します。温度変化による破損もしにくくなっています。この堅牢性により、純銅は長期的な投資として優れています。

炎は、CCAワイヤーではなく純銅ワイヤーを選ぶ理由の一つでもあります。はい、純銅ワイヤーはより耐久性があり、それはより安全な使用につながります。彼らは電気火災を引き起こす可能性が少なく、非常に危険で致命的になることがあります。純銅ワイヤーを使用すれば、あなたの電気システムが安全で効率的に機能し、問題なく動作することを確信できます。

では、純銅ワイヤーの欠点について考えてみましょう。最も明白な欠点は、純銅ワイヤーがCCAワイヤーよりも高価であることです。銅はアルミニウムよりも高価な材料なので、純銅ワイヤーには初期コストがかかります。しかし、この追加費用は、純銅ワイヤーの優れた性能と長寿命によって正当化されます。

CCAワイヤーはアルミニウム製であるため、銅ほど高性能ではなく、安価です。このため、CCAワイヤーはより壊れやすかったり故障しやすかったりします。これが起こった場合、ワイヤーの修理や交換に自己負担で費用を支払う必要があるかもしれません。つまり、CCAワイヤーを使用することで得られると思っていた節約が、修理が必要になる頃には消えてしまう可能性があります。

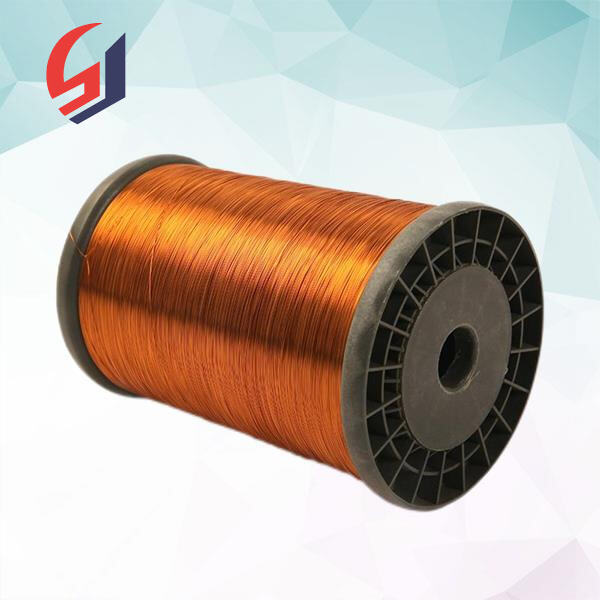

私たちが使用するエナメル線の工場は、最先端の生産技術と厳格な品質管理により、製品を世界中に効率的に配布しています。私たちは国際的な物流パートナーと協力し、顧客の要件に合わせた物流ソリューションを提供しています。私たちのグローバル配送ネットワークは主要な港で構成されており、製品が迅速かつ安全に目的地に到達することを保証します。また、営業スタッフはオンライン追跡サービスを提供しており、顧客が出荷状況を常に把握できるよう、サプライチェーンの透明性を向上させています。

エナメル銅線の高品質は極めて重要です。製造施設では、製品が国際品質基準を満たし、顧客の要求に応えるために、さまざまな品質管理手順を行っています。(1) 原材料のコントロール:純銅から高級絶縁ラッカーまで、原材料は厳格なスクリーニングを受け、その性能が安定していることを確認します。2.) 全工程監視:線引きからエナメル加工まで、生産の各段階で厳密な試験が行われます。これには電気性能、絶縁耐圧、引張り試験が含まれ、品質と安全性を確保します。顧客の信頼を高めるため、品質工場は通常、ISO 9001の品質管理体制やUL安全性認証を取得しています。

私たちのエナメル線工場は、顧客の特別な要件に応じて製品をカスタマイズし、広範なアフターサービスも提供しています。多様な仕様:当社の工場では、線径、エナメルの厚さ、温度格付け、絶縁格付けなど、さまざまな仕様のエナメルケーブルを生産できます。

エナメル銅線工場は、大規模な生産能力により、より安い価格で高品質の製品を作ることができます。(1) 大量生産: 製造施設は大口注文への需要に迅速に対応でき、同時に納期を確保できます。(2) コスト削減。生産プロセスと設備の最適化により、工場は消費を減らし、生産性を向上させ、単位原価を下げ、顧客が価格でより競争力を持てるようにします。