Confronto tra la conducibilità e la durata del rame e del filo CCA.

Il filo CCA, d'altra parte, viene prodotto con un metodo alternativo. È rivestito esternamente in alluminio con un rame puro vs cca nucleo interno. Questa costruzione rende il filo CCA meno costoso rispetto a quello di rame solido. Purtroppo presenta alcuni svantaggi nonostante il costo inferiore — il filo CCA. Non conduce l'elettricità così bene come un filo di rame puro, quindi potrebbe non essere altrettanto efficace in condizioni difficili. Inoltre, il filo CCA non ha una durata così lunga quanto quella del filo di rame, e è più probabile che si deteriori in ambienti ostili.

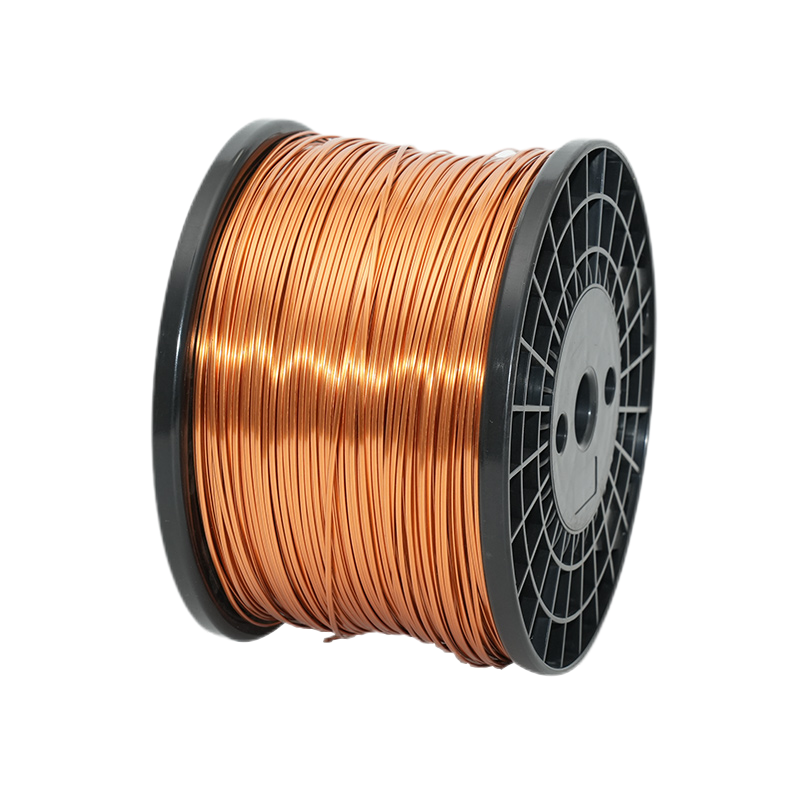

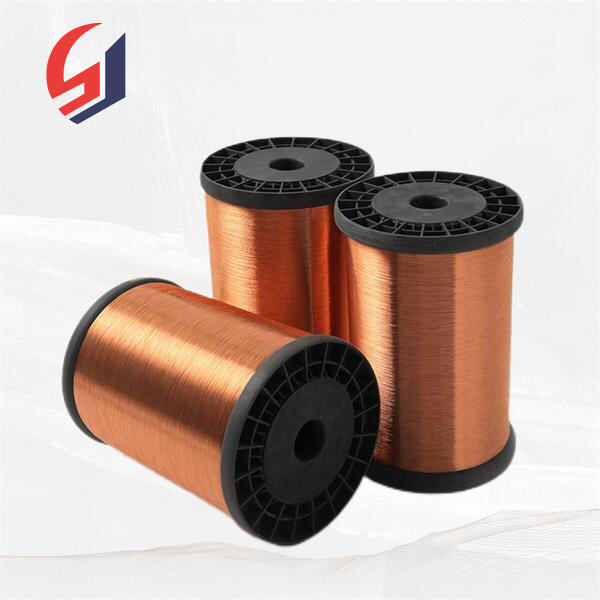

In termini di prezzo, il filo di rame è più costoso del filo CCA. (1) Questo perché il rame è un metallo unico, raro e prezioso. A causa delle sue migliori prestazioni e durata rispetto al filo CCA, molte persone ritengono che sia un buon investimento spendere di più per il filo di rame. Per i progetti elettrici, se desideri il filo di qualità superiore che ti servirà bene, il filo di rame è in cima alla lista.

IT

IT