Apakah Anda tahu bahwa setiap kali Anda menyalakan lampu di rumah atau mengisi daya ponsel Anda, ada kawat listrik khusus yang bekerja keras untuk memberikan daya ke perangkat Anda? Kawat-kawat ini sangat penting untuk operasi lancar dari segala sesuatu. Jenis kawat Ada banyak jenis kawat yang berbeda, dan mungkin dua jenis yang paling umum dikenal sebagai tembaga murni dan CCA. Lalu, apa perbedaan antara kedua jenis kawat ini dan mana yang lebih baik untuk kebutuhan listrik Anda? Kami akan menjelaskan dalam kata-kata sederhana, agar anak kelas tiga seperti Anda bisa memahaminya.

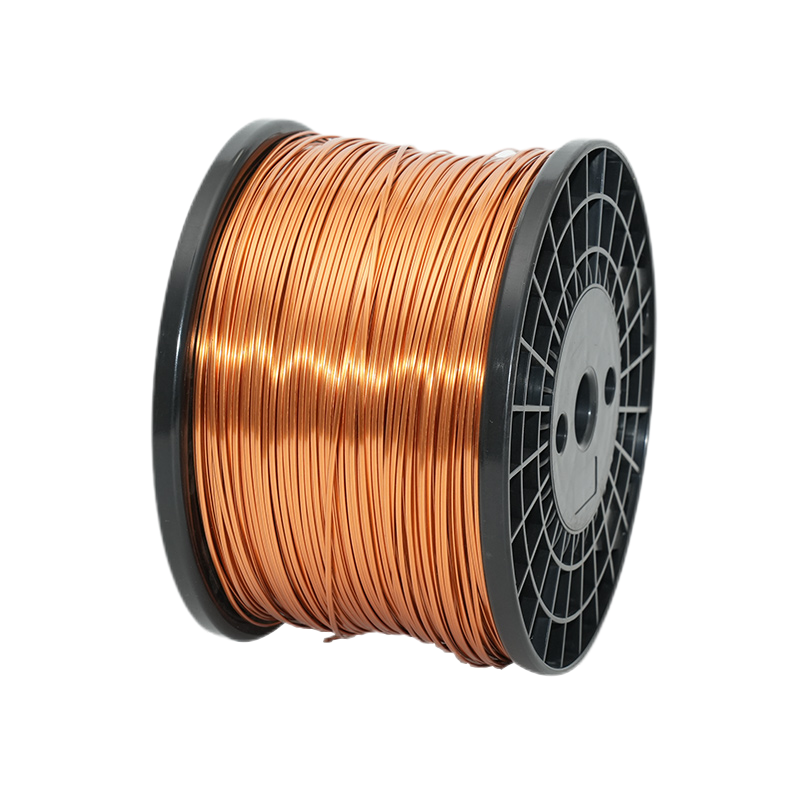

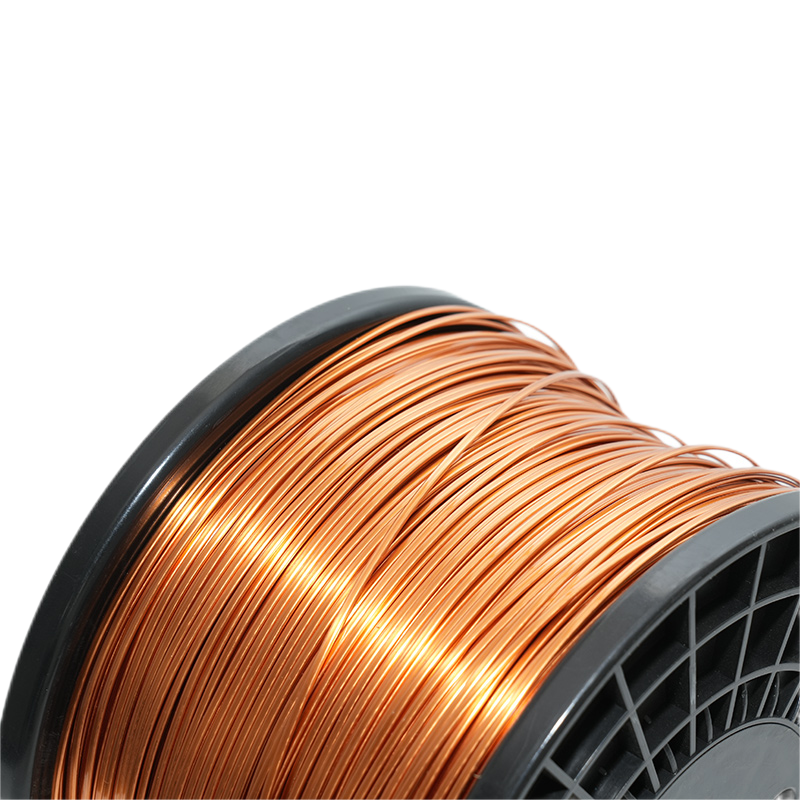

Mari kita mulai dengan kawat tembaga mentah. Sesuai dengan namanya, kawat tembaga murni hanya terdiri dari logam tembaga. Tembaga adalah bahan yang sangat baik karena memungkinkan listrik mengalir dengan cepat dan mudah. Ini berarti bahwa kawat tembaga murni melakukan pekerjaan yang sangat baik dalam mentransmisikan sinyal listrik dari satu tempat ke tempat lain. Mereka sangat cocok untuk perangkat dengan permintaan tinggi yang membutuhkan banyak daya, seperti alat-alat listrik, sistem suara yang memutar musik, dan sistem video yang menampilkan film atau permainan.

ID

ID