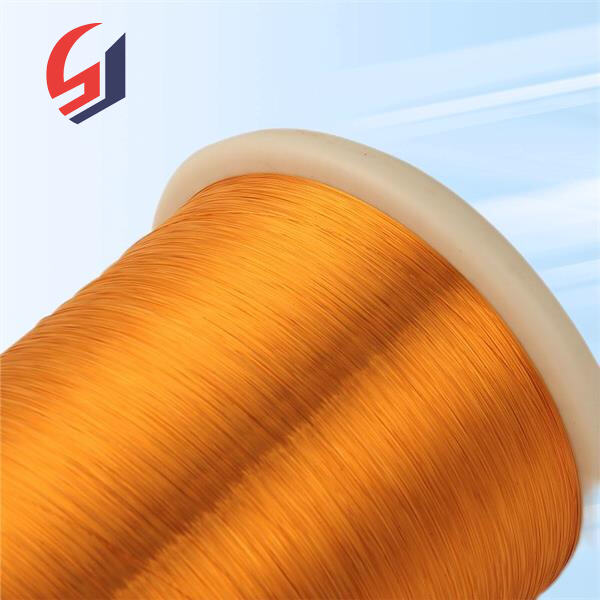

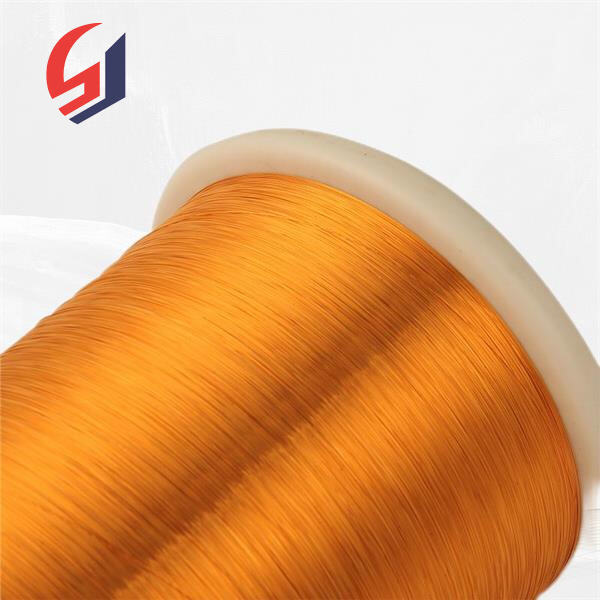

Kawat Copper Clad Aluminum (CCA) adalah jenis kawat listrik yang terdiri dari dua logam berbeda: tembaga dan alumunium. Kawat CCA menjadi favorit banyak orang karena harganya lebih murah dibandingkan kawat tembaga murni. Ini adalah tipe kawat standar yang telah ada selama bertahun-tahun dan dulu sering digunakan dalam sistem listrik apa pun. Dalam artikel ini, kita akan membahas apa itu kawat CCA, alasan mengapa biayanya lebih rendah jika dibandingkan dengan kawat tembaga murni, bagaimana performanya dibandingkan kawat tembaga, tips keselamatan saat menggunakan Shenzhou Cable, KAWAT ECCA (Kawat CCA Email) dan cara memilih kawat CCA yang tepat untuk proyek Anda.

Apa itu kawat Copper Clad Aluminum (CCA)? Kawat ini memiliki lapisan tembaga di bagian luarnya yang dapat melakukan pekerjaan dengan baik dalam menghantarkan listrik. Kemudian, kawat ini memiliki banyak kawat aluminium di dalamnya yang memberikan kekuatan dan dukungan. Kawat CCA lebih murah daripada tembaga, dengan harga yang lebih terjangkau dibandingkan tembaga, membuatnya menjadi pilihan yang lebih baik untuk beberapa proyek listrik. Ini adalah pilihan yang sangat umum bagi orang-orang yang ingin menjaga biaya tetap rendah, namun tetap mendapatkan kawat berkualitas baik untuk pekerjaan mereka.

ID

ID