Jeste li znali da svaki put kad upalite svjetla u kući ili nabijate telefon, postoje posebne električne žice koje borave s prirodnim problemima prilikom davanja struja vašim uređajima? Ove žice su vrlo važne za neprekinuti rad svega. Vrste žica Postoji više različitih vrsta žica, a vjerojatno su dvije najčešće poznate vrste čiste bakarne i CCA. Pa što je razlika između ovih dviju vrsta žica i koja je bolji izbor za vaše električne potrepstine? Objasnit ćemo to jednostavnim riječima, tako da i trogradečki poput vas mogu razumjeti.

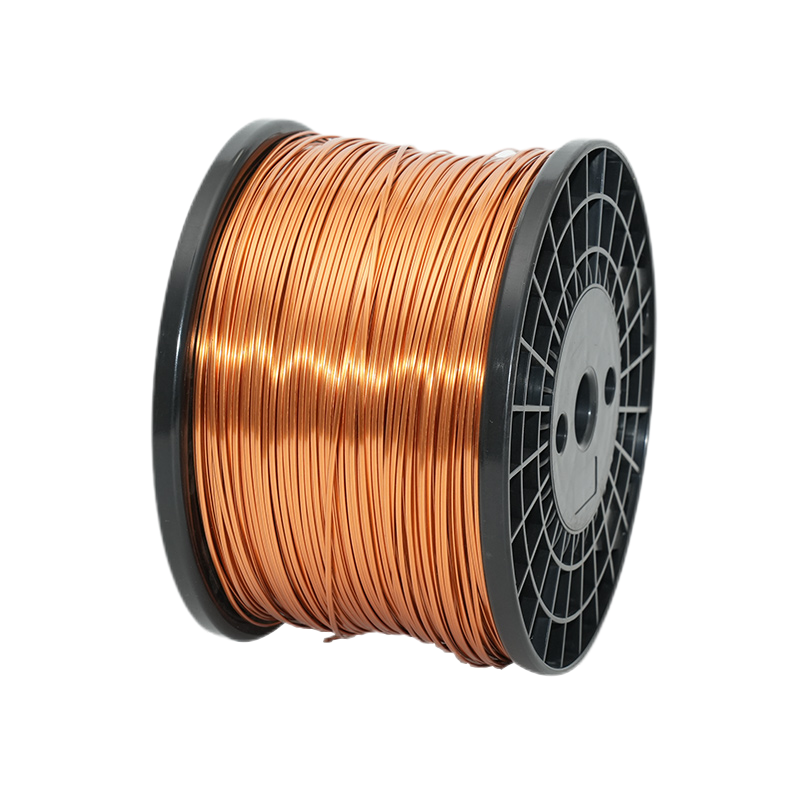

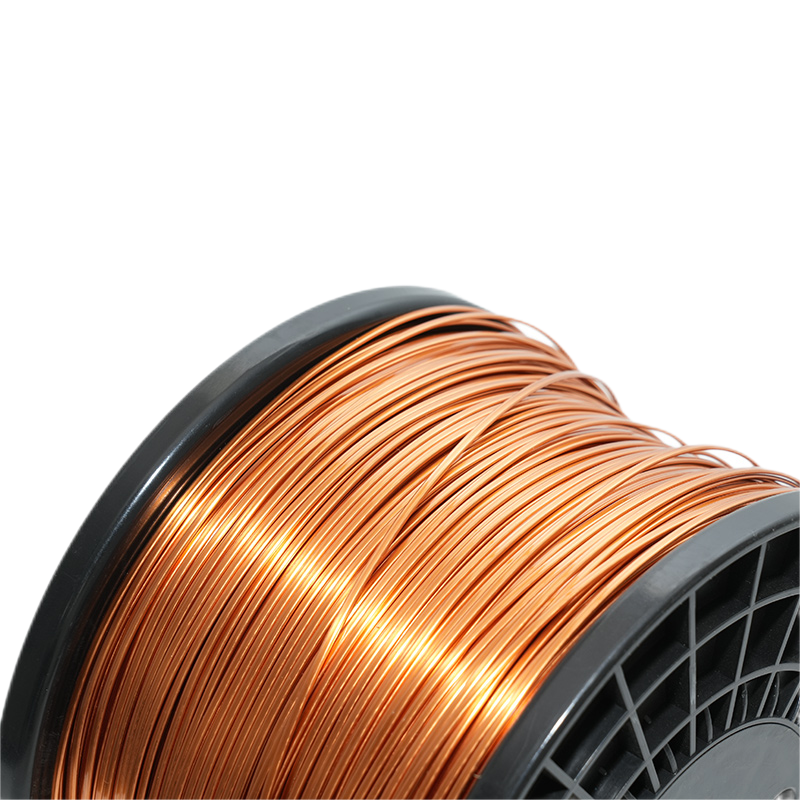

Počnimo s neobradjenim bakrenim žicama. U skladu sa svojim nazivom, čiste bakrene žice sastoje se isključivo od bakra. Bakar je tako dobar materijal zato što omogućava brzo i lako prolazak struje. To znači da čiste bakrene žice izvrsno rade u prenosu električnih signala s jednog mjesta na drugo. Posebno su prilagođene uređajima s visokim zahtjevima koji troše puno energije, kao što su elektro alati, zvučni sustavi koji puštaju glazbu i video sustavi koji prikazuju filmove ili igre.

HR

HR