Draad is 'n tipe dun, buigbare materiaal wat elektriese impulsies van een plek na 'n ander dra. Dit werk soos 'n pad vir elektrisiteit, wat dinge wat krag gebruik verbind, soos ligte, rekenaars en televisies. Wanneer jy ooit CCA-draad hoor, is dit 'n algemene tipe draad wat baie mense gebruik.

CCA beteken Koper Omgewikkelde Aluminium. Dus, cca-draad is in werklikheid twee tipes metale: koper en aluminium. Binne die draad is aluminium, 'n ligwaterige metaal. Daar is ook 'n dun laag koper, 'n baie geleiende metaal, rondom die buitekant van die draad. Weens hierdie unieke kombinasie is hierdie koper-omgewikkelde aluminiumdraad goedkoper as suiwer koperdraad, maar dit behou sommige van die voordelige eienskappe van koper wat nuttig is.

CCA-draad is lig en maklik om te hanteer, wat die rede is waarom dit dikwels in karre en skepe gebruik word. Dit is ligweeg, wat baie kan tel vir prestasie, aangesien dit nie te veel gewig aan voertuie byvoeg nie. Maar daar is sleutelverwagtinge wat jy rekening mee moet hou wanneer jy CCA-draad hanteer. Byvoorbeeld, is CCA-draad nie so goed lei as suiwer koperdraad nie. Dit beteken dat dit moontlik nie ideaal sal wees vir toestelle wat 'n groot hoeveelheid krag benodig om soos bedoel te funksioneer nie. Verder is CCA-draad moontlik nie so duurzaam as suiwer koperdraad nie, veral onder swaarvoorwaardes.

Wanneer jy probeer besluit of jy CCA-draad of reen koperdraad moet kies, oorweeg wat jou projek regtig nodig het. Vir 'n liggere en goedkoper draad kan jy CCA-draad kies. Dit doen gewoonlik 'n redelik goeie werk by baie alledaagse take. Maar as jy 'n draad benodig met uitstekende gelei-vermoë wat lank en wyd gebruik sal word, dan wil jy reen koperdraad hê. Hulle is uitstekend vir veelspeling, maar jy moet die draad by die taak pas sodat dit vloei en nie bederf nie.

Daar is verskeie voordele om CCA-draad in karre en botte te gebruik. Die eerste rede waarom CCA-draad nie roes of korrosieer nie, is dat sy CCA dit langer duur laat, veral in swaar of nat omgewings. Dit is spesifiek nodig in areas waar water waarskynlik teenwoordig sal wees, soos binne in botte. Dit is ook lig, wat krities is wanneer gewig invloed het op spoed en doeltreffendheid. So is die hantering van CCA-draad baie maklik. Dit beteken dat dit veel vinniger en makliker te installeer is, wat jou werklik geld en tyd bespaar tydens die installasie van die konfigurasie.

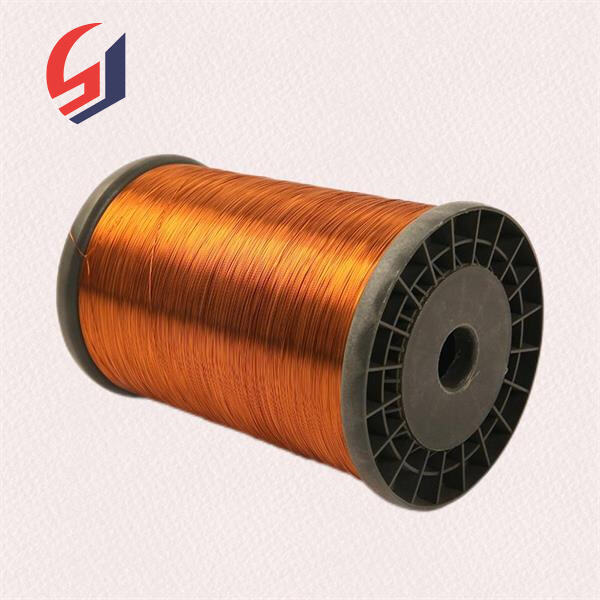

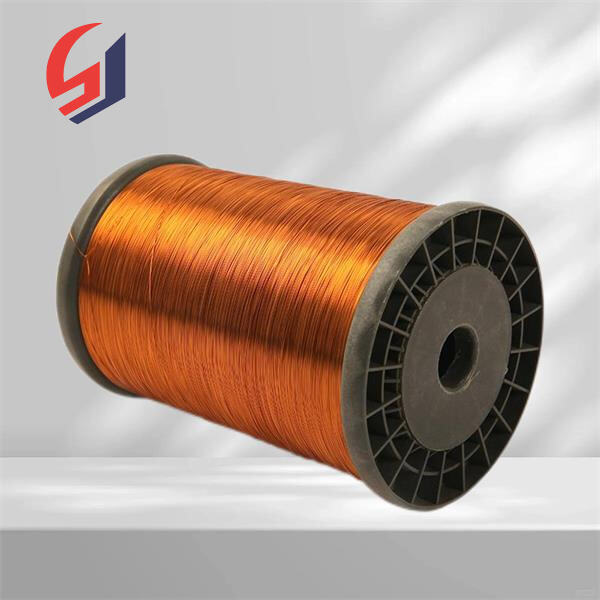

Koperdraadfabrieks wat email kan, kan hoë-kwaliteitsprodukte teen goedkope pryse produseer weens hul geskaalde produksiekapasiteit. (1) Massaproduksie: Die fabriek kan vinnig op groot bestellings reageer en tegelykertyd verseker dat die lewerdatum tydig is. (2) Koste-verlaging deur meer doeltreffende produksie en optimalisering van toerusting kan verbruik verminder en uitset verhoog, wat lei tot 'n verlaagde eenheidskost en kliente 'n meer mededingerige prys bied.

Ons emaildraadfabriek is in staat om produkte aan te pas om klante se spesifieke vereistes te voldoen. Hulle bied ook volledige naverkoopsdienste. Verskeie spesifikasies: Die fabriek is in staat om emaildraad te produseer wat 'n wye verskeidenheid spesifikasies dek, wat verskillende draaddiameters, emaildiktes, temperatuurklasse en isolasieklassering insluit om 'n verskeidenheid toepassings te pas.

Ons kabelfabrieken wat geëmailleer word, verseker doeltreffende lewering van produkte wêreldwyd dankie aan die nuutste vervaardigingstegnologie en streng kwaliteitsbeheer. In samewerking met ons logistiekparters in die wêreld kan ons geskikte logistieke oplossings skep om die spesifieke behoeftes van verskillende klante te voldoen. Ons wêreldwye netwerk van leweringsparters sluit sleutelhavens in om seker te stel dat die goederse vinnig en veilig by hul bestemming aankom. Verkoops personeel by ons maatskappy bied ook aanlyn naspoor dienste wat ons klante opdater oor die vooruitskatting van hul versendings, wat die deursigbaarheid van die voorsieningsketting verbeter.

Die hoë kwaliteit van emaildraadkoper is van groot belang. Die vervaardigingsaanleg ondergaan 'n verskeidenheid kwaliteitscontroles om seker te maak dat die kwaliteit van die produkte in lyn is met internasionale standaarde en klantebehoeftes bevredig. (1) Beheer van ruwe materiaal Van suiwer koper, tot hoë-kwaliteit isoleringslakkery, ondergaan al die ruwe materialen streng skerming om stabiliteit in prestasie te verseker. (2) Kontinu prosesbewaking: Van draadtrekking tot emaliëring, ondergaan elke stadium van produksie strenge toetse, insluitend treksterkte, asook elektriese en isolasie-spanningstandtoetse, om die kwaliteit van die produk te verseker. Om klantevertroue te verhoog, word kwaliteitswerwe gewoonlik gecerifieer deur ISO 9001 vir hul kwaliteitsbestuursstelsel, sowel as UL Veiligheidsertifisering.